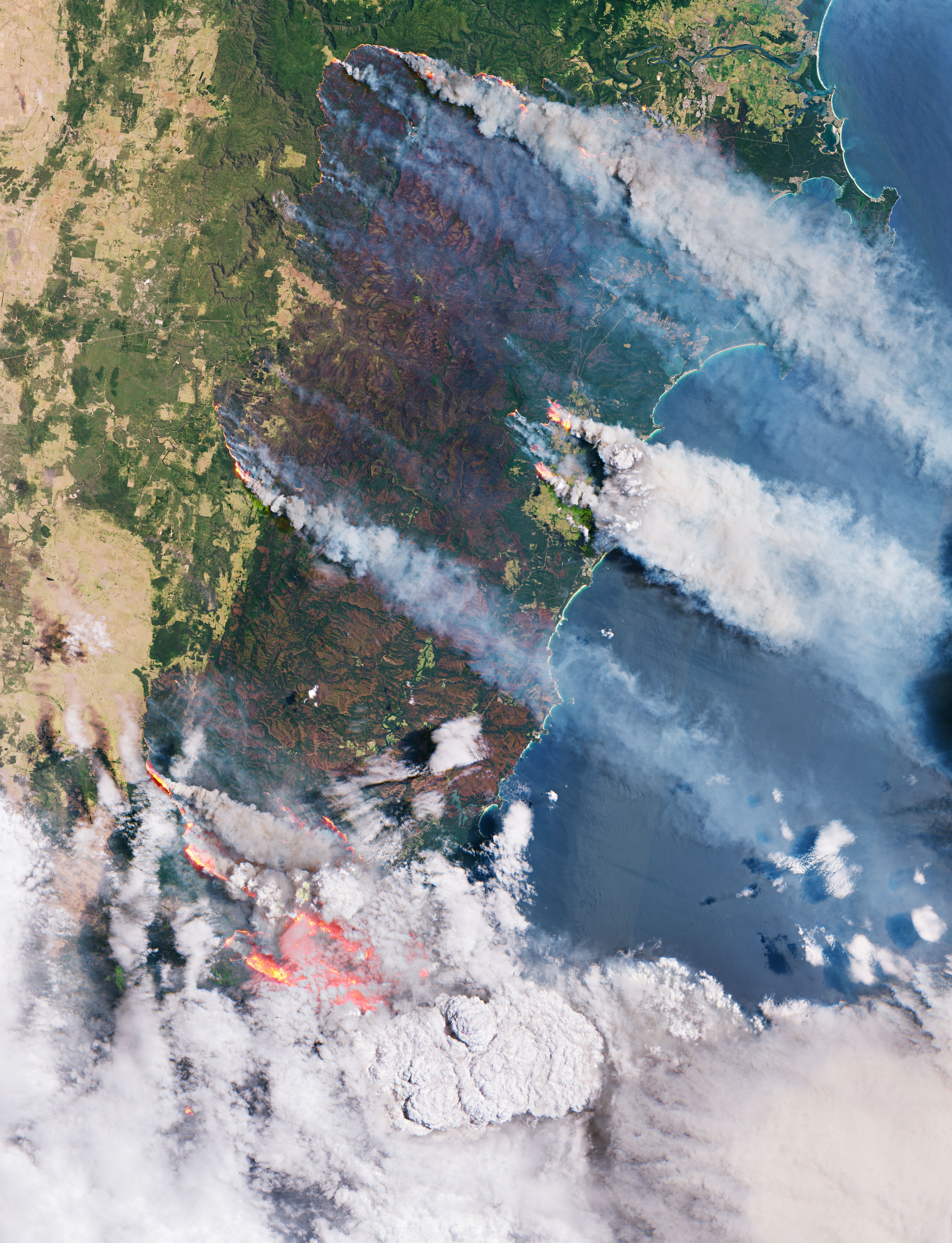

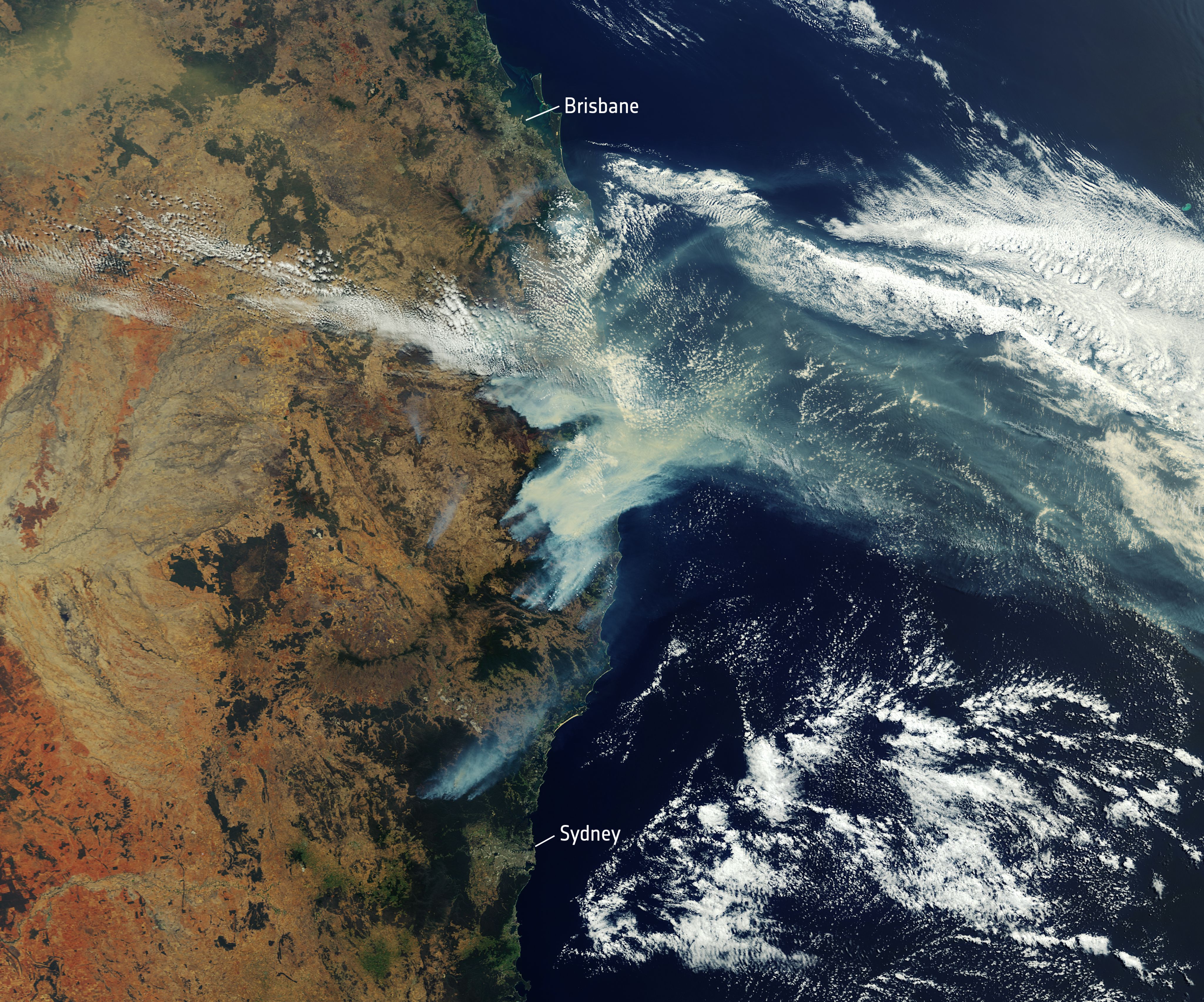

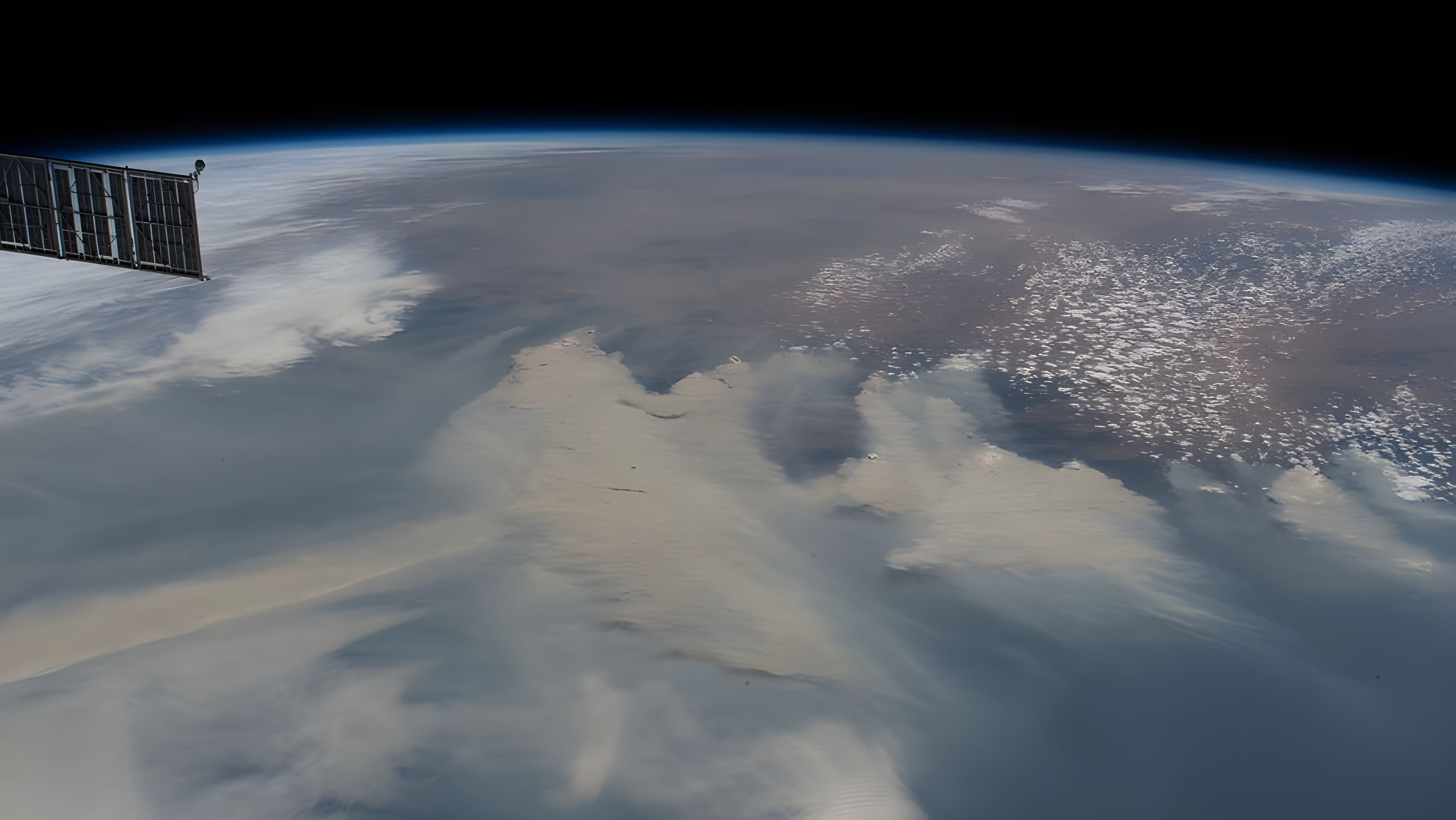

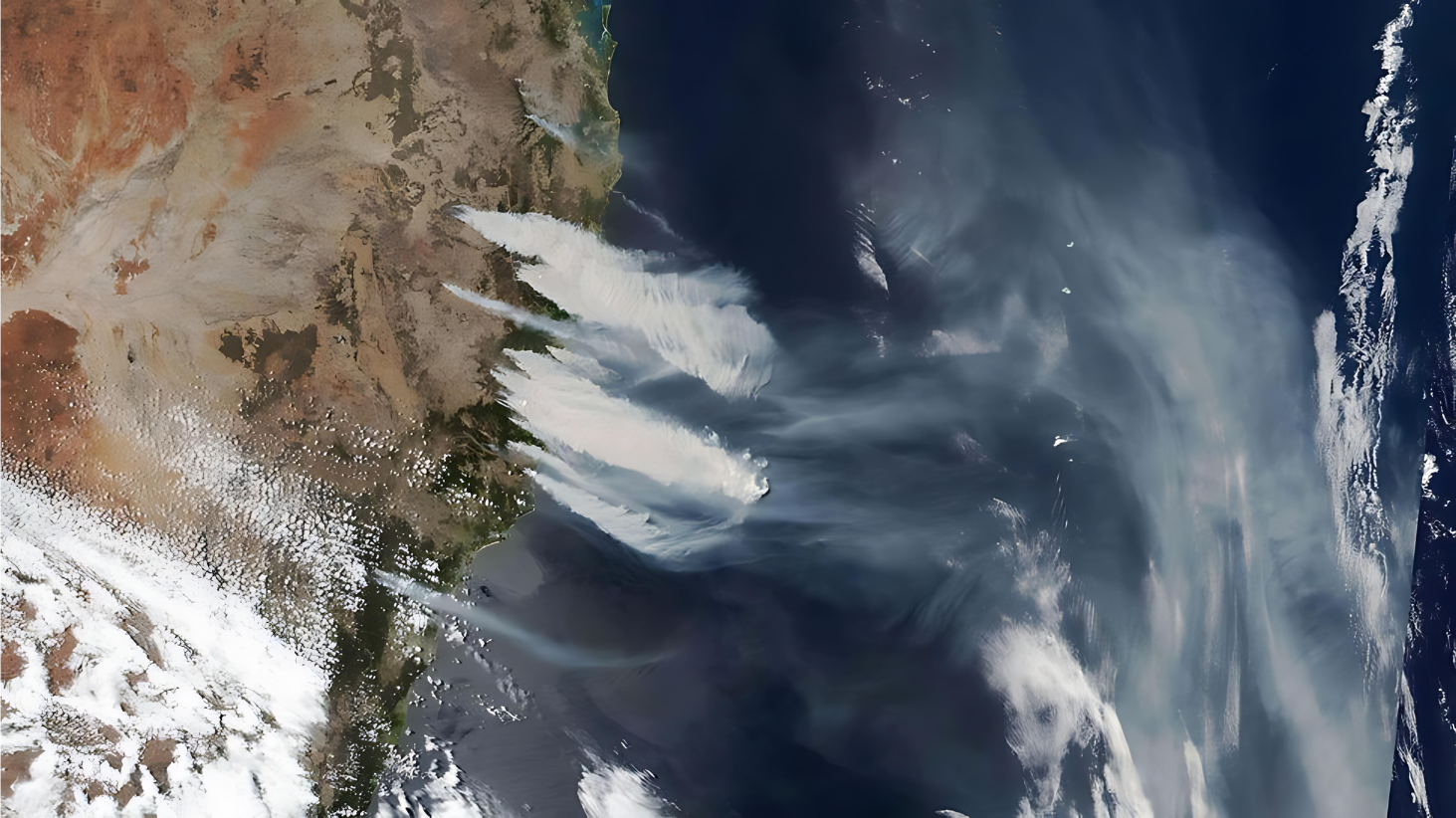

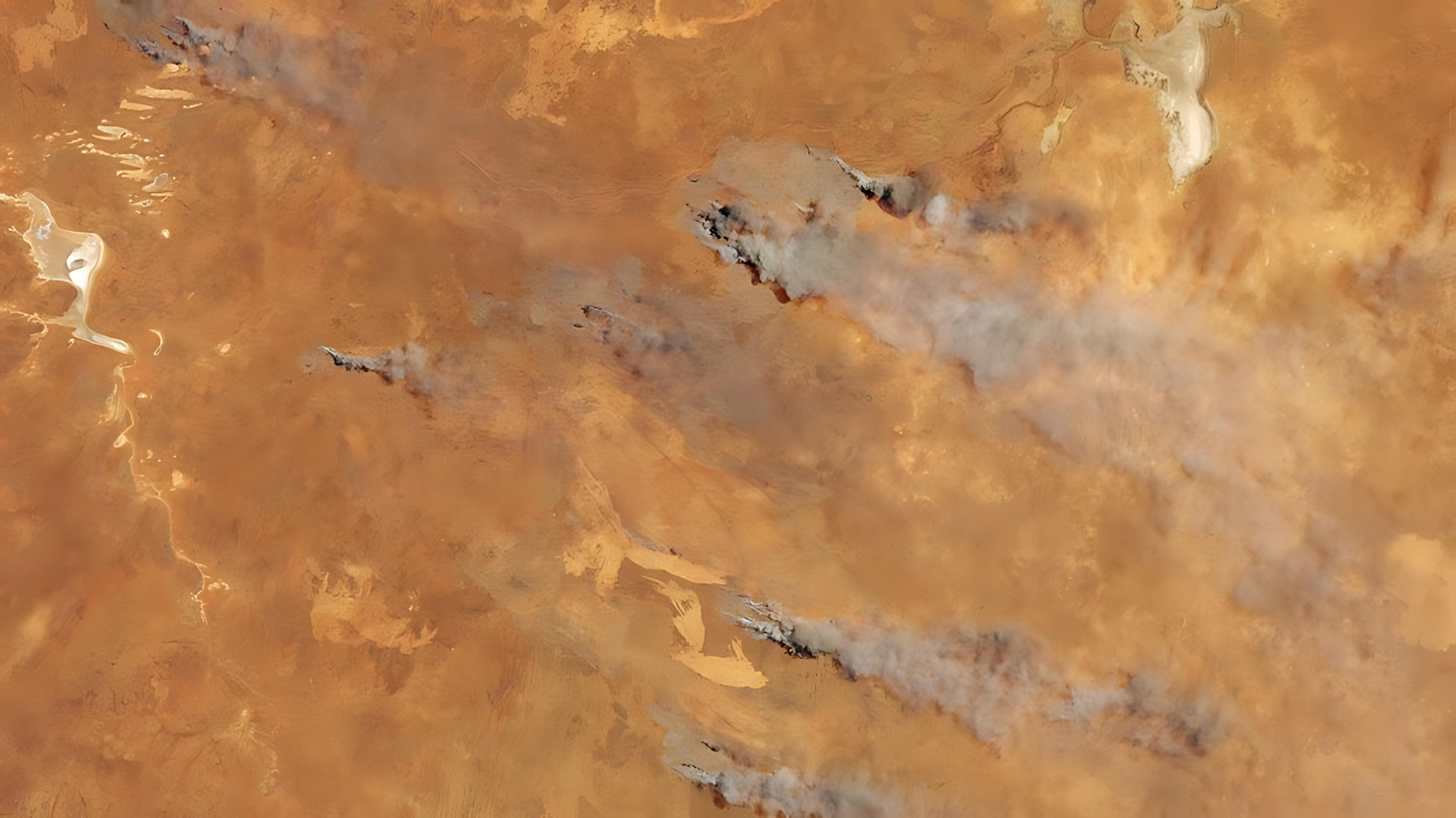

Five years ago, Australia's Black Summer pressed home the power of space.

Hundreds of fires swept across the nation's south-east, burning an area almost the size of the UK and killing at least 34.

To help coordinate the firefighting response, Japan’s Himawari-9 geostationary satellite delivered a photographic overview of the unfolding catastrophe every 10 minutes.

Until it didn't.

“It was retasked to focus on the Japanese coastline because they were having a disaster event at exactly the same time,” said Professor Anna Moore, Founding Director of the Australian National University Institute for Space.

“We lost critical intel because we had nothing to respond with. We didn’t have a sovereign capability. We assume these space-based services will always be there. And we don’t realise we don’t own or control it until it’s gone.”

It’s an issue that impacts everything from weather forecasting to research data, crop management to industrial coordination, as well as national security.

Australia is the world’s 12th largest economy. But since 2007, it has fallen 26 places on the global Economic Complexity rankings, to 93rd out of 133 countries.

“That’s a pretty depressing statistic for someone like me,” Ben Adams, Chief Operating Officer of Inovor Technologies, told create. “Space is cool, right? Obviously, I’m a convert. But we’re not doing space for space’s sake. We’re doing it because we want to contribute to real life, to solve real problems.

“And together, we’re solving the big problems for our own country, reducing our reliance on other countries’ companies to do that for us.”

It’s an issue that impacts everything from weather forecasting to research data, crop management to industrial coordination, as well as national security.

Australia is the world’s 12th largest economy. But since 2007, it has fallen 26 places on the global Economic Complexity rankings, to 93rd out of 133 countries.

“That’s a pretty depressing statistic for someone like me,” Ben Adams, Chief Operating Officer of Inovor Technologies, told create. “Space is cool, right? Obviously, I’m a convert. But we’re not doing space for space’s sake. We’re doing it because we want to contribute to real life, to solve real problems.

And together, we’re solving the big problems for our own country, reducing our reliance on other countries’ companies to do that for us.”

Space to grow

By Jamie Seidel, Joseph Harding, Heath Dunn, and Amanda Caliao

Australia’s struggle to turn its world-renowned creativity into commercial success is not a secret. Now, the information-based era of advanced manufacturing offers a huge opportunity to change this pattern. And one of the greatest opportunities to showcase our talents is in the commercialisation of space.

“This is a bit cheeky, but I think our ignorance helps us compete with Europe and North America,” Dr Lyle Roberts, Head of Photonics at robotics innovation company Advanced Navigation, said. “It’s a mentality of not knowing how hard something is, but giving it a shot anyway. That gives us an edge. We’re not just sitting around doubting ourselves.”

But the right guidance is crucial.

“There’s no issue with Australia having the capability,” Professor Peter Moar FIEAust, Chair of the Engineers Australia National Committee for Space Engineering, said. “There are so many companies here that don’t know what they don’t know. They’re more than capable, but they need the right guidance and infrastructure, and to be overseen by people of international mastery level who can ease them on their way.”

Building capability is one thing, but leveraging that capability for national benefit is another story, according to Adams.

“Securing our intellectual property and keeping it within Australian companies has spin-offs for government, defence and commercial needs,” he said. “But it also grows export markets and the money returns to Australia.

“When we achieve these things, we’re lifting the whole country. It’s economic growth. It’s jobs with higher salaries because it’s advanced manufacturing. From this, everybody earns well, opening up more avenues to reinvest back into the Australian economy, thereby improving the quality of our lives and the generations to come.”

But Australia needs to hold firm.

“It is a tough time in Australia’s space industry,” the interim CEO of the Space Industry Association of Australia, Lisa Vitaris CompIEAust EngExec, told create. “There are government grants, but not a lot of government funding. And the industry has a high bar to leap to commercialisation. On the flip side is the resilience it’s displaying. Our members are finding other ways to do business with their technology.”

Enabling innovation

University of Southern Queensland iLAuNCH Program Chief Technology Officer Dr Joni Sytsma is among those trying to make a difference.

“Our academic sector is filled with early-stage technology research,” the US-born aerospace engineer said. “It ranks extremely high worldwide. And then we fall off a cliff.”

Australia has produced a lot of very young space startup companies, Sytsma said. But the sector is still dominated by multinational “primes” who import their own products and focus on sustainability contracts.

“Australian industry comes to us wanting to build a product,” she said. “They’re coming to us partly because of the grant money, but also partly because they don’t have the capabilities they need. That means equipment, people, the know-how or intellectual property, or all of the above.”

Enabling such innovation is about to pay off, Vitaris said. This year, the world’s biggest players will flood into Australia for the International Astronautical Congress. Representatives from up to 100 countries will be keen to observe our potential up close.

“They want to partner with us because of the innovation we have, but also because of the benefits of our geography and the part of the world we’re in,” Vitaris said. “I’m not sure our businesses are fully aware of the opportunities this will bring.”

Transformative ideas

Adams is extremely impressed with the quality of graduates coming out of universities.

“We have a growing skill base across the many different sectors of the space industry. And when you partner us all together, we have an opportune moment.”

Innovation is vital to information services and advanced manufacturing. But we also need to sustain a skilled workforce.

“When it comes to jobs generated and sustained in Australia, we have to ensure the companies we establish realise most jobs will come from securing projects in the international market,” Moar warned. “Our domestic market is just too small.”

Sytsma agreed.

“I’ve found that Australia has some incredible capability,” she said. “But I’d say it’s on an Australian scale. And that makes it difficult to turn that capability into a global export.”

Increasing value

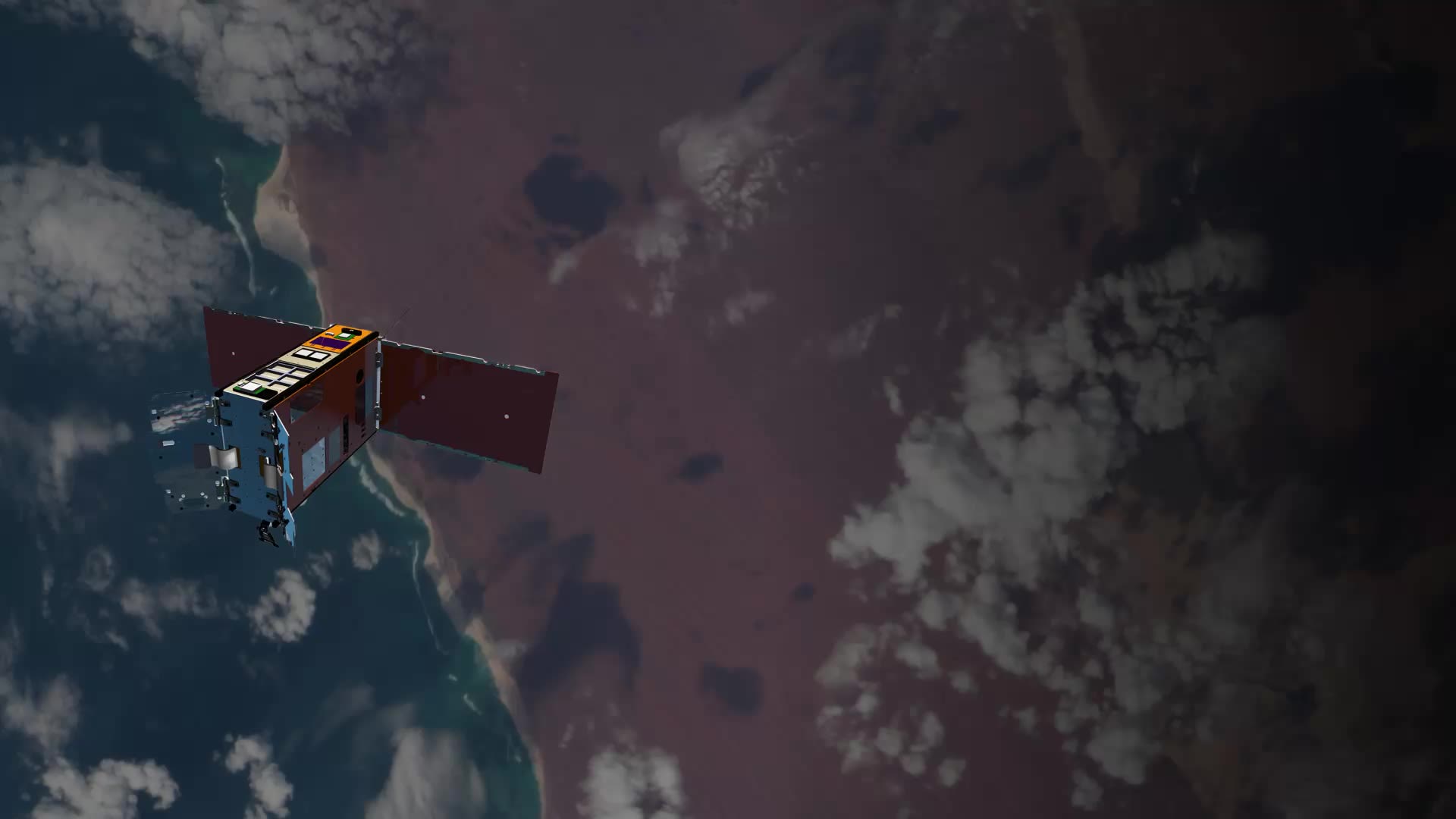

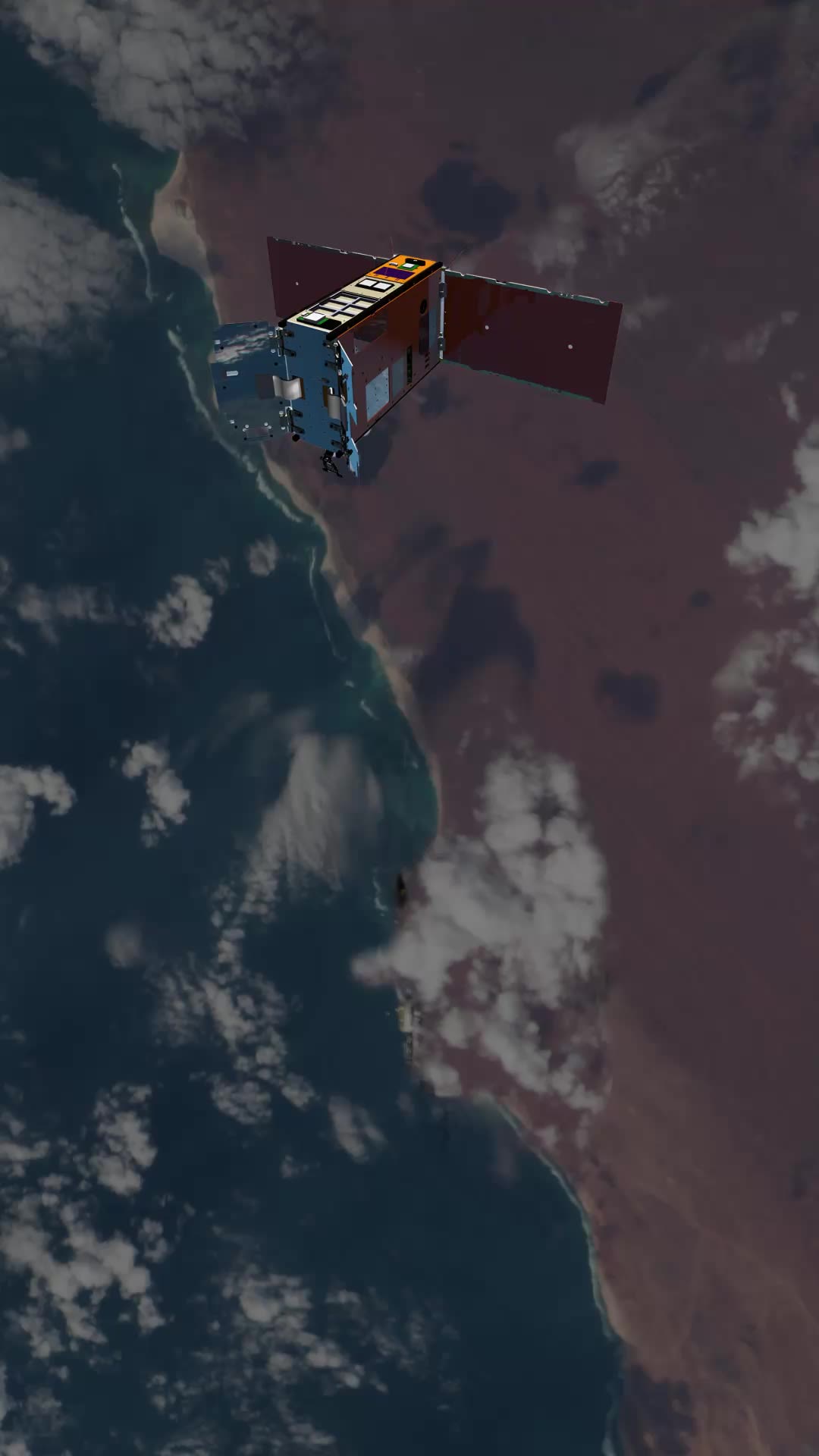

Access to space is getting easier, cheaper and faster, but it’s not the satellite or its payload that is inherently valuable or even innovative. It’s what’s done with the data it collects, relays and assembles, and how it’s built.

“It isn’t just the technical people and engineers with great ideas,” Moore said. “It includes people that can use their services – those doing water purification, food growth in remote locations, real-time telehealth, remote monitoring of equipment.”

The challenge isn’t just the technology, Adams agreed.

“The thing that goes with innovation is mindset. Entrepreneurial thinking needs innovation. It requires a belief that we can be better than everyone else in the world – and that it’s okay to be proud of that.

“It requires the ability to win the hearts and minds of government, defence and the population at large. It’s about showing people how space capabilities drive our nation forward to solve its big problems.”

Full of promise

Australia’s space industry has come a long way in recent years. The ANU’s National Space Test Facility at Mount Stromlo is “going gangbusters”, according to Moore. And in December, ELO2 Consortium – touted as the most advanced robotics project in the country – was chosen to build and operate Roo-ver, Australia’s first lunar robot.

The technical challenges unique to space travel all need very specific and expensive testing equipment.

“You’re not going to be able to go up [to space] and fix it. That’s where engineering comes in. It’s totally different. It’s very bespoke. It’s an extremely difficult environment. And that’s where you need a coordinated front door to all the help you’ll inevitably need.”

“It’s the ability to help anyone get their products qualified for a space environment. That way, they don’t have to lose one or two prototypes before they succeed. And it helps them get on the international supply chain, which is important because we don’t have the domestic market to ramp these companies up.”

Industry, government and academia have pooled resources in various projects across Australia. For example, there is the University of Southern Queensland’s iLAuNCH Space Hub; the Lot Fourteen Innovation Precinct, which houses many space companies; the Australian Space Agency in the heart of Adelaide; the Cicada National Space Industry Hub; and the ANU InSpace Canberra collaborative institute.

Their goal is to provide practical, intellectual and moral support. “We don’t want to see different companies make the same mistake twice,” Sytsma said.

Then there are the titanium crafting machines, 3D-multi-metals printers, circuit board printers and composite materials kilns. No advanced manufacturing startup can afford all the extreme-precision machinery it needs – nor can an entirely new national industry.

Australia aims to grow its space industry market from around 10,000 jobs and $3.9 billion to 30,000 jobs and $12 billion by 2030. That will take investment, commitment and a national effort. Here are just some examples.

At a national level, the SmartSat CRC is a consortium of universities and other research organisations, partnered with industry and funded by the Australian Government to develop know-how and technologies in advanced telecommunications and IoT connectivity, intelligent satellite systems and Earth observation next generation data services.

The Australian Space Manufacturing Network is a collaboration of more than 30 Australian space manufacturing businesses aiming to build common manufacturing and testing facilities, as well as operating the Bowen Orbital Spaceport. It is funded by the Australian Government’s Modern Manufacturing Initiative, the Queensland Government and member businesses.

South Australia

Let’s start in the state with the most to show for it. In Adelaide, the South Australian Space Industry Centre (SASIC) is home to more than 100 space-related companies. The Lot Fourteen precinct (within SASIC) is home to the Australian Space Agency, Australian Space Discovery Centre, SmartSat Cooperative Research Centre and Responsive Space Operations Centre (RSOC), Australia’s first national mission control centre.

In Ceduna, the Koonibba Test Range is the largest commercial rocket testing facility in the Southern Hemisphere, specialising in suborbital launches and returns from space. Southern Launch completed the first launch of German company HyImpulse’s suborbital rocket from Koonibba in May 2024.

And on the Eyre Peninsula, the Whalers Way Orbital Launch Complex is South Australia’s second space launch facility and supports orbital launches into polar and sun-synchronous orbits.

Western Australia

In Perth, the Australian Space Automation AI and Robotics Control Complex (SpAARC) is a remote operations centre that trains, tests and controls remote and autonomous operations in space and other harsh environments.

Northern Territory

In Alice Springs, the Centre for Appropriate Technology (CfAT) Satellite Enterprises manages a 38-ha Space Precinct on which it hosts two satellite ground stations.

Queensland

The Bowen Orbital Spaceport at Abbot Point has just been issued with the Australian Government’s first ever commercial orbital launch permit. Gilmour Space is scheduled to launch the Eris 1 rocket in 2025.

NSW

The National Space Industry Hub in Sydney provides support to innovators trying to commercialise their technology in the space, aerospace and defence sectors by providing support tailored to the needs of each business.

ACT

The National Space Test Facility at ANU in Canberra enables the development of major space missions through severe space environmental testing of satellites, payloads, sub-systems and components.

The Australian National Concurrent Design Facility (ANCDF) at UNSW Canberra has developed and operated four small satellite missions over the past 10 years.

Victoria

The Space Industry Hub at RMIT University leverages Victoria’s advanced manufacturing capabilities to develop next-generation space suits and componentry for a new lunar rover.

Tasmania

Last but not least, the Mount Pleasant Radio Observatory enables tracking of low earth orbit satellites.

Space to grow

By Jamie Seidel, Joseph Harding, Heath Dunn, and Amanda Caliao

Australia’s struggle to turn its world-renowned creativity into commercial success is not a secret. Now, the information-based era of advanced manufacturing offers a huge opportunity to change this pattern. And one of the great opportunities to showcase our talents is in the commercialisation of space.

“This is a bit cheeky, but I think our ignorance helps us compete with Europe and North America,” Dr Lyle Roberts, Head of Photonics at robotics innovation company Advanced Navigation, said. “It’s a mentality of not knowing how hard something is, but giving it a shot anyway. That gives us an edge. We’re not just sitting around doubting ourselves.”

But the right guidance is crucial.

“There’s no issue with Australia having the capability,” Professor Peter Moar FIEAust, Chair of the Engineers Australia National Committee for Space Engineering, said. “There are just so many companies here that don’t know what they don’t know. They’re more than capable, but they need the right guidance and infrastructure, and to be overseen by people of international mastery level who can ease them on their way.”

Building capability is one thing, but leveraging that capability for national benefit is another story, according to Adams.

“Securing our intellectual property and keeping it within Australian companies has spin-offs for government, defence and commercial needs,” he said. “But it also grows export markets and the money returns to Australia.

“When we achieve these things, we’re lifting the whole country. It’s economic growth. It’s jobs with higher salaries because it’s advanced manufacturing. From this, everybody earns well, opening up more avenues to reinvest back into the Australian economy, thereby improving the quality of our lives and the generations to come.”

But Australia needs to hold firm.

“It is a tough time in Australia’s space industry,” the interim CEO of the Space Industry Association of Australia, Lisa Vitaris CompIEAust EngExec, told create. “There are government grants, but not a lot of government funding. And the industry has a high bar to leap to commercialisation. On the flip side is the resilience it’s displaying. Our members are finding other ways to do business with their technology.”

Enabling innovation

University of Southern Queensland iLAuNCH Program Chief Technology Officer Dr Joni Sytsma is among those trying to make a difference.

“Our academic sector is filled with early-stage technology research,” the US-born aerospace engineer said. “It ranks extremely high worldwide. And then we fall off a cliff.”

Australia has produced a lot of very young space startup companies, Sytsma said. But the sector is still dominated by multinational “primes” who import their own products and focus on sustainability contracts.

“Australian industry comes to us wanting to build a product,” she said. “They’re coming to us partly because of the grant money, but also partly because they don’t have the capabilities they need. That means equipment, people, the know-how or intellectual property, or all of the above.”

Enabling such innovation is about to pay off, Vitaris said. This year, the world’s biggest players will flood into Australia for the International Astronautical Congress. Representatives from up to 100 countries will be keen to observe our potential up close.

“They want to partner with us because of the innovation we have, but also because of the benefits of our geography and the part of the world we’re in,” Vitaris said. “I’m not sure our businesses are fully aware of the opportunities this will bring.”

Transformative ideas

Adams is extremely impressed with the quality of graduates coming out of universities.

“We have a growing skill base across the many different sectors of the space industry. And when you partner us all together, we have an opportune moment.”

Innovation is vital to information services and advanced manufacturing. But we also need to sustain a skilled workforce.

“When it comes to jobs generated and sustained in Australia, we have to ensure the companies we establish realise most jobs will come from securing projects in the international market,” Moar warned. “Our domestic market is just too small.”

Sytsma agreed. “I’ve found that Australia has some incredible capability,” she said. “But I’d say it’s on an Australian scale. And that makes it difficult to turn that capability into a global export.”

Increasing value

Access to space is getting easier, cheaper and faster, but it’s not the satellite or its payload that is inherently valuable or even innovative. It’s what’s done with the data it collects, relays and assembles, and how it’s built.

“It isn’t just the technical people and engineers with great ideas,” Moore said. “It includes people that can use their services – those doing water purification, food growth in remote locations, real-time telehealth, remote monitoring of equipment.”

The challenge isn’t just the technology, Adams agreed.

“The thing that goes with innovation is mindset. Entrepreneurial thinking needs innovation. It requires a belief that we can be better than everyone else in the world – and that it’s okay to be proud of that.

“It requires the ability to win the hearts and minds of government, defence and the population at large. It’s about showing people how space capabilities drive our nation forward to solve its big problems.”

Full of promise

Australia’s space industry has come a long way in recent years. The ANU’s National Space Test Facility at Mount Stromlo is “going gangbusters”, according to Moore. And in December, ELO2 Consortium – touted as the most advanced robotics project in the country – was chosen to build and operate Roo-ver, Australia’s first lunar robot.

The technical challenges unique to space travel all need very specific and expensive testing equipment.

“You’re not going to be able to go up [to space] and fix it. That’s where engineering comes in. It’s totally different. It’s very bespoke. It’s an extremely difficult environment. And that’s where you need a coordinated front door to all the help you’ll inevitably need.”

“It’s the ability to help anyone get their products qualified for a space environment. That way, they don’t have to lose one or two prototypes before they succeed. And it helps them get on the international supply chain, which is important because we don’t have the domestic market to ramp these companies up.”

Industry, government and academia have pooled resources in various projects across Australia. For example, there is the University of Southern Queensland’s iLAuNCH Space Hub; the Lot Fourteen Innovation Precinct, which houses many space companies; the Australian Space Agency in the heart of Adelaide; the Cicada National Space Industry Hub; and the ANU InSpace Canberra collaborative institute.

Their goal is to provide practical, intellectual and moral support. “We don’t want to see different companies make the same mistake twice,” Sytsma said.

Then there are the titanium crafting machines, 3D-multi-metals printers, circuit board printers and composite materials kilns. No advanced manufacturing startup can afford all the extreme-precision machinery it needs – nor can an entirely new national industry.

Australia aims to grow its space industry market from around 10,000 jobs and $3.9 billion to 30,000 jobs and $12 billion by 2030. That will take investment, commitment and a national effort. Here are just some examples.

At a national level, the SmartSat CRC is a consortium of universities and other research organisations, partnered with industry and funded by the Australian Government to develop know-how and technologies in advanced telecommunications and IoT connectivity, intelligent satellite systems and Earth observation next generation data services.

The Australian Space Manufacturing Network is a collaboration of more than 30 Australian space manufacturing businesses aiming to build common manufacturing and testing facilities, as well as operating the Bowen Orbital Spaceport. It is funded by the Australian Government’s Modern Manufacturing Initiative, the Queensland Government and member businesses.

South Australia

Let’s start in the state with the most to show for it. In Adelaide, the South Australian Space Industry Centre (SASIC) is home to more than 100 space-related companies. The Lot Fourteen precinct (within SASIC) is home to the Australian Space Agency, Australian Space Discovery Centre, SmartSat Cooperative Research Centre and Responsive Space Operations Centre (RSOC), Australia’s first national mission control centre.

In Ceduna, the Koonibba Test Range is the largest commercial rocket testing facility in the Southern Hemisphere, specialising in suborbital launches and returns from space. Southern Launch completed the first launch of German company HyImpulse’s suborbital rocket from Koonibba in May 2024.

And on the Eyre Peninsula, the Whalers Way Orbital Launch Complex is South Australia’s second space launch facility and supports orbital launches into polar and sun-synchronous orbits.

Western Australia

In Perth, the Australian Space Automation AI and Robotics Control Complex (SpAARC) is a remote operations centre that trains, tests and controls remote and autonomous operations in space and other harsh environments.

Northern Territory

In Alice Springs, the Centre for Appropriate Technology (CfAT) Satellite Enterprises manages a 38-ha Space Precinct on which it hosts two satellite ground stations.

Queensland

The Bowen Orbital Spaceport at Abbot Point has just been issued with the Australian Government’s first ever commercial orbital launch permit. Gilmour Space is scheduled to launch the Eris 1 rocket in 2025.

NSW

The National Space Industry Hub in Sydney provides support to innovators trying to commercialise their technology in the space, aerospace and defence sectors by providing support tailored to the needs of each business.

ACT

The National Space Test Facility at ANU in Canberra enables the development of major space missions through severe space environmental testing of satellites, payloads, sub-systems and components.

The Australian National Concurrent Design Facility (ANCDF) at UNSW Canberra has developed and operated four small satellite missions over the past 10 years.

Victoria

The Space Industry Hub at RMIT University leverages Victoria’s advanced manufacturing capabilities to develop next-generation space suits and componentry for a new lunar rover.

Tasmania

Last but not least, the Mount Pleasant Radio Observatory enables tracking of low earth orbit satellites.

Consistency is key

“The more complex technology is, the more imperative there is on the government to provide base load funding of a quantum over two to three decades to really establish an industry and ensure that it survives,” Moar argued.

“The biggest issue Australia has is this very short-burst funding cycle. The experience of Germany, the UK and South Korea shows that we need to adopt a strategy – and execute it with minimal noise. And that takes political will to recognise its value and to put in place the technical mastery needed to execute a plan.”

Innovation isn’t a problem and nor is dedication.

“I feel like Australia has that can-do attitude, which means that if we just had all the right ingredients, we could retain our expertise and use that to support the next wave of innovation technology,” Roberts said. “We can be a massive global player if we support our own industry beyond giving out grant money.”

Fear of commitment

The Australian space industry is slowly getting there.

“Upstream space is a very nascent sector for us,” Moore said. “We don’t have many runs on the board yet. But we had virtually none just seven years ago.”

Australia doesn’t have the ecosystem that Europe, the US or the UK has.

“It’s getting easier. We’re starting to see a lot of our payloads reaching space now. But the technical challenge is often insignificant compared to navigating national and international regulations and standards.”

However, follow-through is needed for lasting results.

“If the previous government hadn’t made the announcement to establish a space agency, then Fleet Space, Inovor – all these other Australian companies wouldn’t exist,” Moar said. “That was the right signal to send to the world – that we’re being serious about space and everything that goes with it.”

That signal must now be reinforced to access the international supply chain and secure Australia’s manufacturing future.

“We’re not just too small to succeed, we’re also too fragmented. Our ecosystem is too fragmented when it comes to producing real manufacturing innovation”.

That fracturing means cooperation and collaboration between those in the industry is critical for future success. Conferences such as the International Astronautical Congress, to be held next in Australia in September, are well-placed to tackle this problem.

Find out more at iac2025.org

Made in Australia

International experience has shown such challenges are not insurmountable. Moar advocates for adopting the Fraunhofer-Gesellschaft model of economic stimulation, which he said has been central to the success of space and other technology-based industries globally. He points to the example of the German city of Kaiserslautern. who set an agreed strategic industry path and appointed an independent institution to oversee the project.

Twenty years on and Kaiserslautern is a world-leading city in artificial intelligence and software development. Without this sort of nation-building, we just get short-term thinking, Moar said.

“The politicians go: ‘I don’t see the votes in this’. The investors go: ‘This is too risky’. As entrepreneurs, scientists and engineers, we have to get much better at selling the story about how this kind of innovation leads to manufacturing jobs and economic success.”

The Future Made in Australia plan and the National Reconstruction Fund could help drive this change, Moar said.

Sytsma said she had already experienced a major commercial partner uprooting everything and moving to the US. Inducements included free buildings, tax concessions and access to collaborative networks. All provided a greater opportunity to produce a profit.

“If we don’t support our businesses, they are right to go to greener pastures,” she said. “We should carefully consider, from a political standpoint, whether our pastures are green enough for businesses. Because if they’re not, they won’t stay here. They can take their jobs with them, and all their tax money too.”

On a personal level, Australia’s engineering innovators want to stay. But they know their boards of directors must deliver shareholders a dividend.

Roberts leads the innovation and development of an advanced, but compact, autonomous navigation sensor to safely land spacecraft on the moon. The instrument is on board US company Intuitive Machines’ lander, which will launch later this year.

“Everyone working on this project here at Advanced Navigation is so passionate about it, and we want to be able to continue that,” he said. “I’m not even halfway through my career, so I’m thinking about how cool would it be if I knew there will be opportunities to do this kind of stuff here, in Australia, for another 15 years. And that can only happen with a flourishing and vibrant space industry.”

Attend three conferences for the price of one. Register now for the Australian International Aerospace Congress and also get access to two more conferences and free rein at the Avalon International Airshow.

More from create

For more on building Australia's manufacturing capability, check out these stories:

The Brisbane Olympics could mean gold for local manufacturing

“We can leverage this exposure to show that we are technology leaders with innovative design solutions.”

The engineering behind Australia’s first two space launch facilities

Koonibba and Whalers Way on the Eyre Peninsula are launchpads for bolstering our space capacity.

Advancing Australia’s potential for advanced manufacturing

Technologies such as robotics, artificial intelligence and 3D printing are rapidly changing the country.