Revitalising a Sydney landmark

Inside the new Sydney Fish Market's ambitious engineering

Words by Lachlan Haycock

Video by Carlos Manaog

Graphics: 3XN, Mott MacDonald, supplied

The Sydney Fish Market, established at its current location in Blackwattle Bay almost 60 years ago, is undergoing a massive revitalisation.

More than simply another project, the replacement market is designed to drive a variety of social, commercial and sustainable outcomes.

The building is big in all senses of the word. The site is the size of three football fields, reaches as high as 25 m and boasts a timber roof that, once completed, will be the largest by mass in the southern hemisphere.

Here, we dive deep into the design and construction of the new market, exploring the impact of hydrostatic pressure on the building’s basement level, how the roof’s modular design and innovative building services achieve sustainability outcomes, and why the use of design for manufacture and assembly was a critical decision made by the engineering team.

Image captions

Designing the new market

The key decisions that drove the location of the new market, and why

the use of precast concrete proved critical.

The new Sydney Fish Market, which received funding from Infrastructure NSW and was constructed by Multiplex, encapsulates the kind of engineering project where decisions are not only technical; civic and environmental considerations have also been necessary throughout design and construction.

The first of many considerations that architectural design partnership 3XN/BVN and engineering firm Mott MacDonald took in their approach to the market was its location.

“We discussed the possibility of housing the new facility on the existing site,” Lead Structural Engineer Graham Babcock MEng CEng MICE, who has worked for Mott MacDonald for almost two decades, told create. “The challenge with that, of course, is that it’s an operational facility – the market would need to close down for a number of years.

“Another location considered was Wentworth Park, located just to the south of the site. But the City of Sydney and the NSW Government were keen to maintain as much public green space in the area as possible.”

In the end, following extensive consultation with local and state governments, 3XN/BVN, Mott MacDonald and the broader design team decided not to disrupt operations and to instead build a new facility immediately adjacent to the existing one – a facility that, once completed, will be ready for tenants to move into from day one with minimal disruption to trading.

A facility of such ambition is prone to significant design challenges.

“Safety is a massive concern,” Babcock explained. “In the existing market, there are trucks and forklifts moving in and around people, and so the separation of operations from the retail function was one of the first design decisions made by the team.”

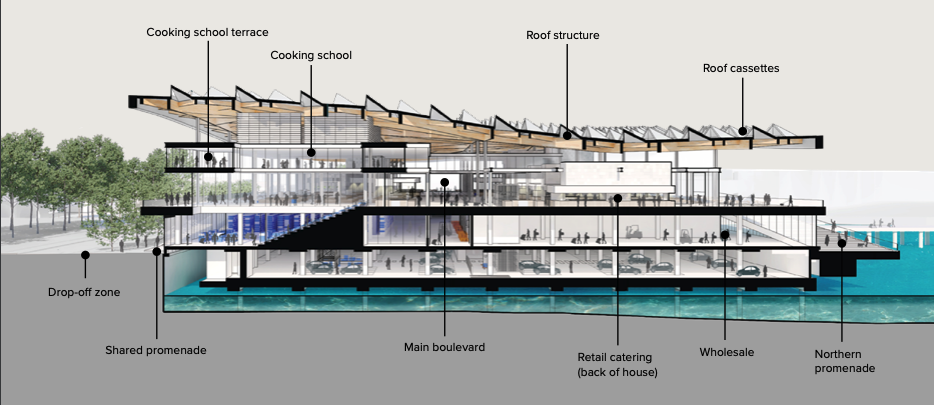

Michael Calcoen, Technical Director – Built Environment at Mott MacDonald, described the vertically integrated design best suited the site constraints and unique requirements of the market.

He said it was a significant achievement for a building to enable such a variety of functions, including the flow of incoming and outgoing products, a wholesale market, retail services, operations and even a seafood cooking school.

“It is most important for a market such as this to maintain the quality and temperature consistency of its products,” Calcoen told create. “When products arrive at the market in the late afternoon or at night, they must be kept at the right temperature to prevent spoiling – meaning there is a range of temperature settings that must be achieved throughout the building.

“We’re talking four or five different temperature zones as you move through the building, ranging from normal air-conditioned spaces at 21-23°C, down to 14°, 0° and -22° in some areas. The market is basically a massive fridge-freezer.”

The old market is almost entirely horizontal in layout. By contrast, the new vertically integrated market, from basement to mezzanine, considers the segregation of operations and public spaces, while also providing significantly improved visibility of market operations to the public.

This approach involved assessing the vertical transportation of people and goods, and how building services are reticulated through the building.

Designing for assembly

Design for manufacture and assembly (DfMA) proved

critical to unlocking innovation.

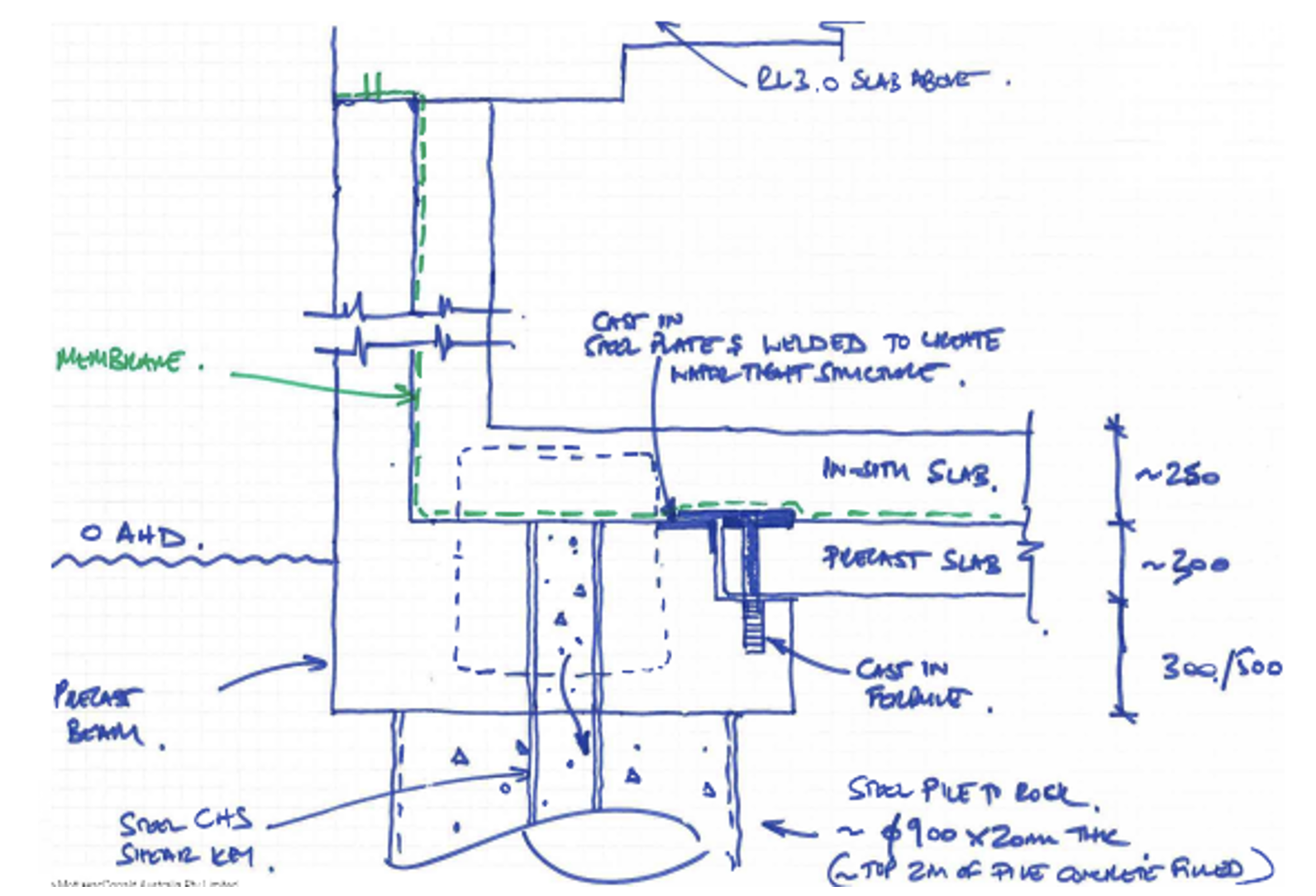

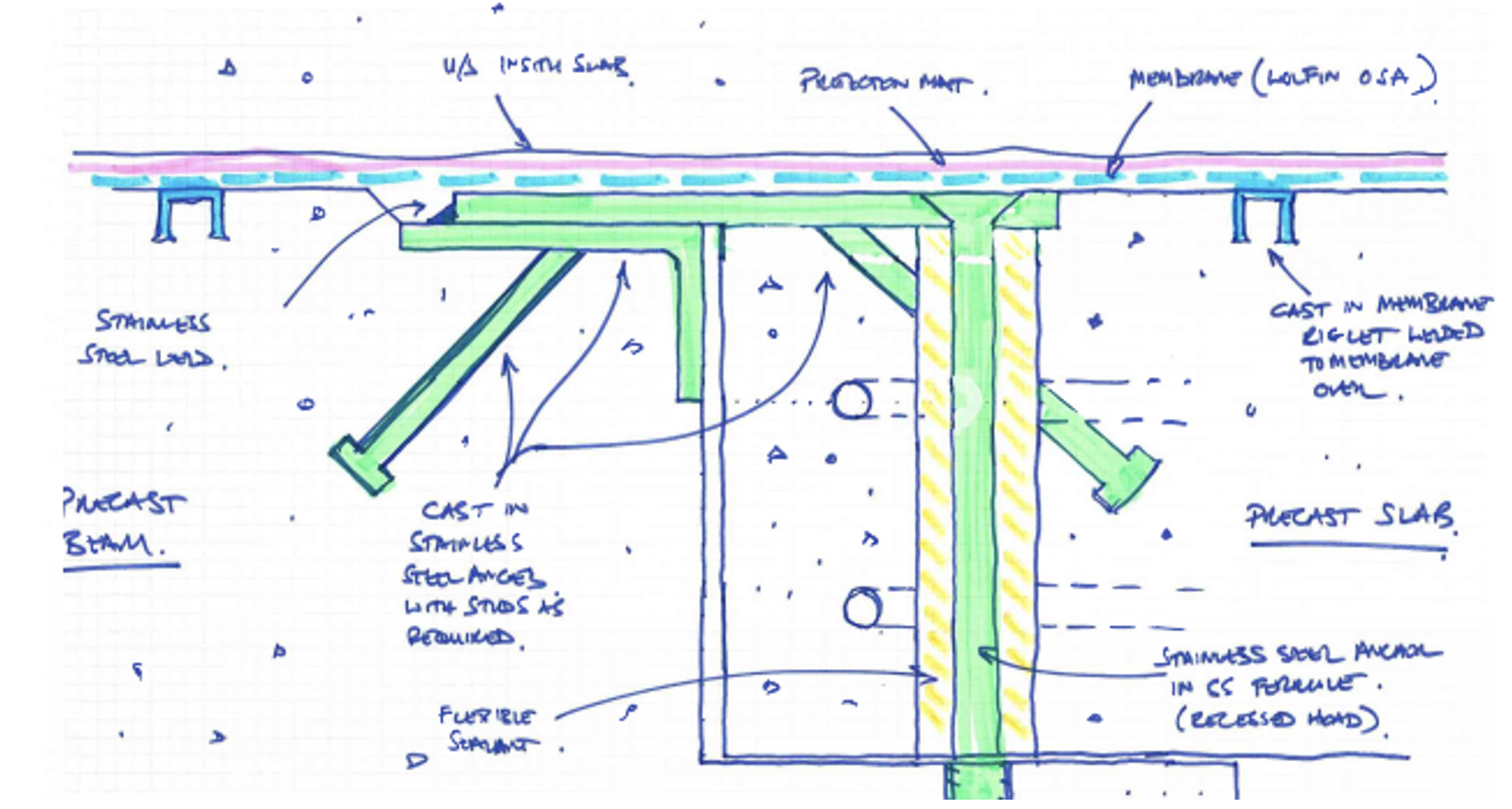

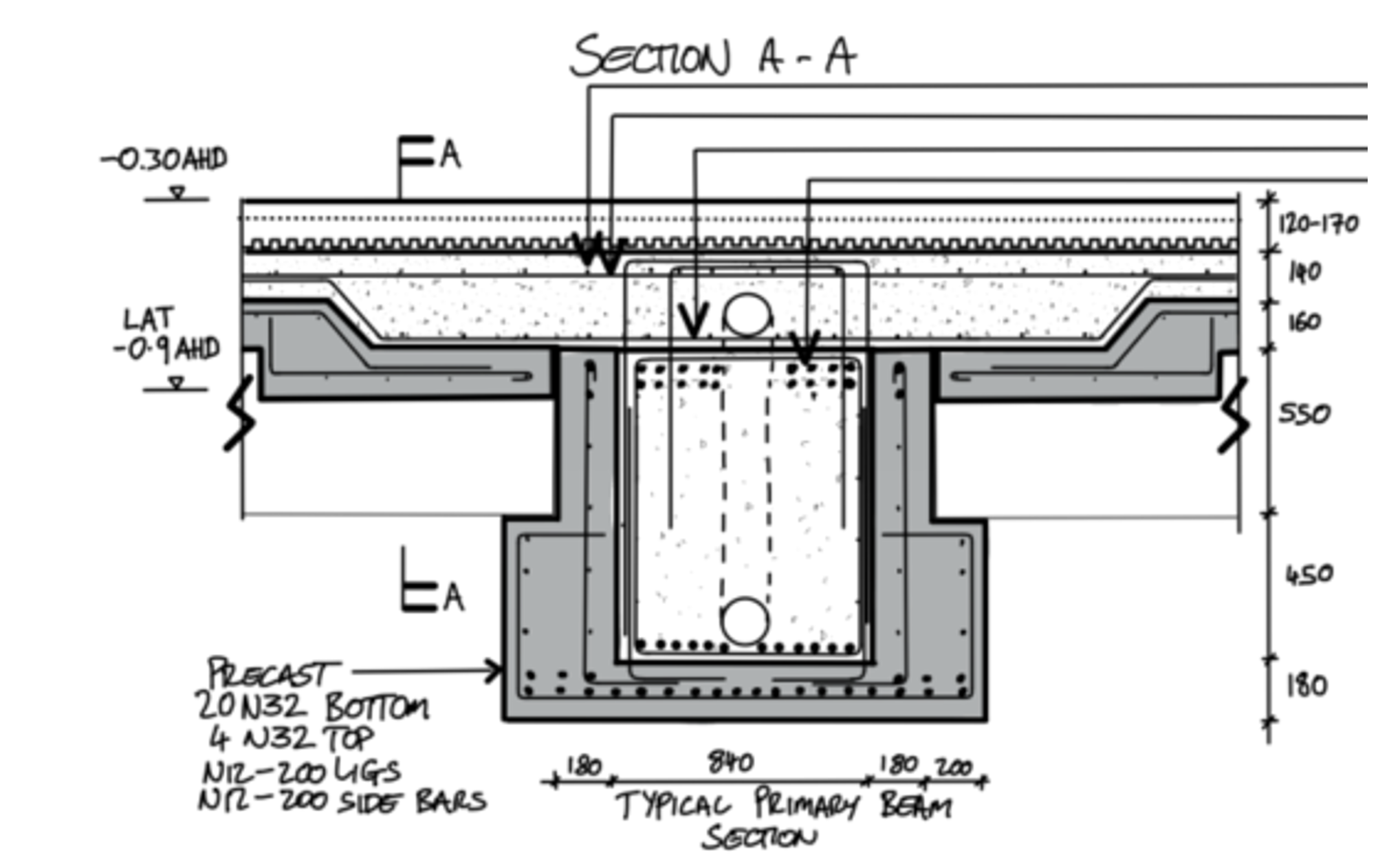

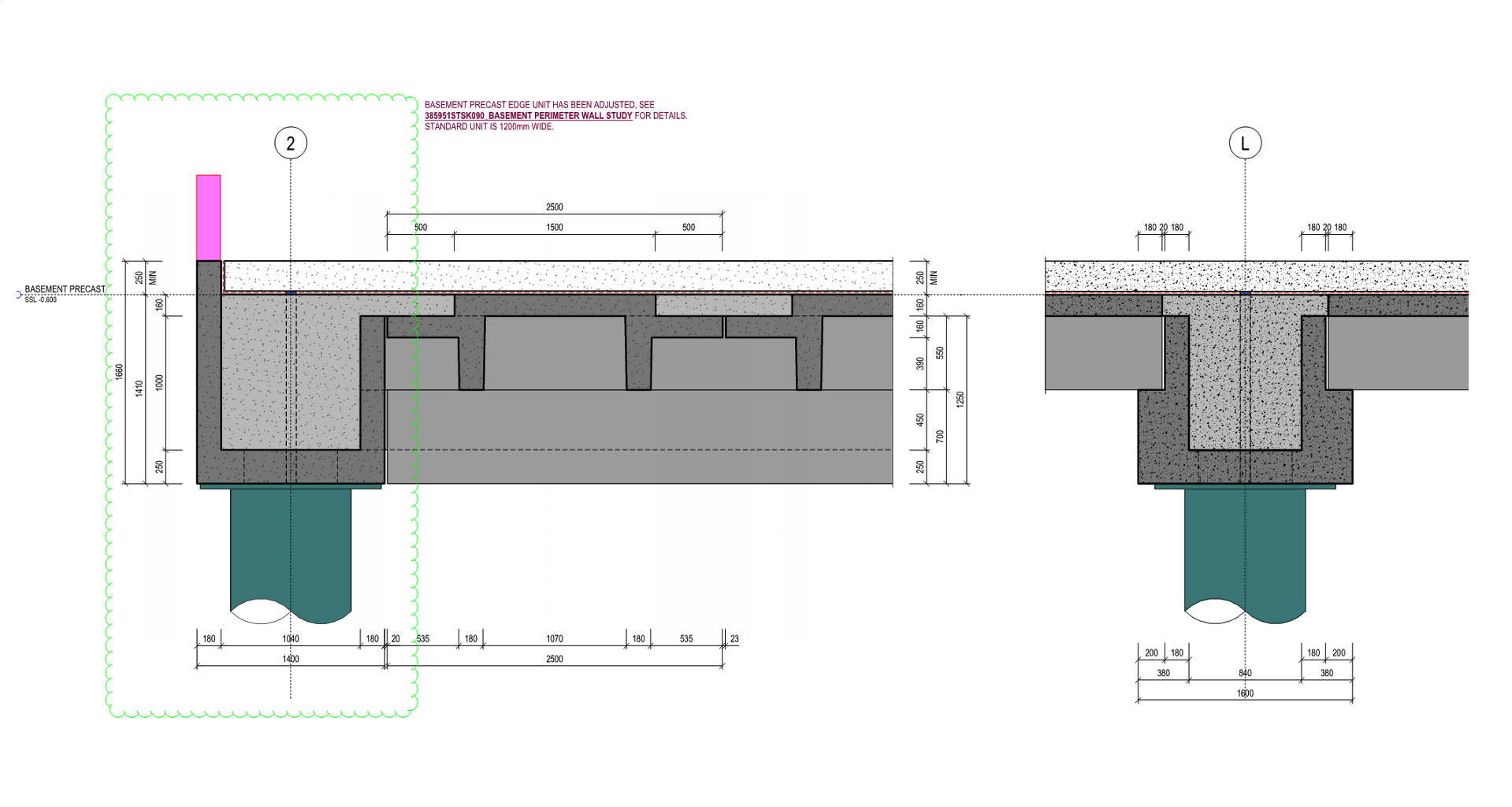

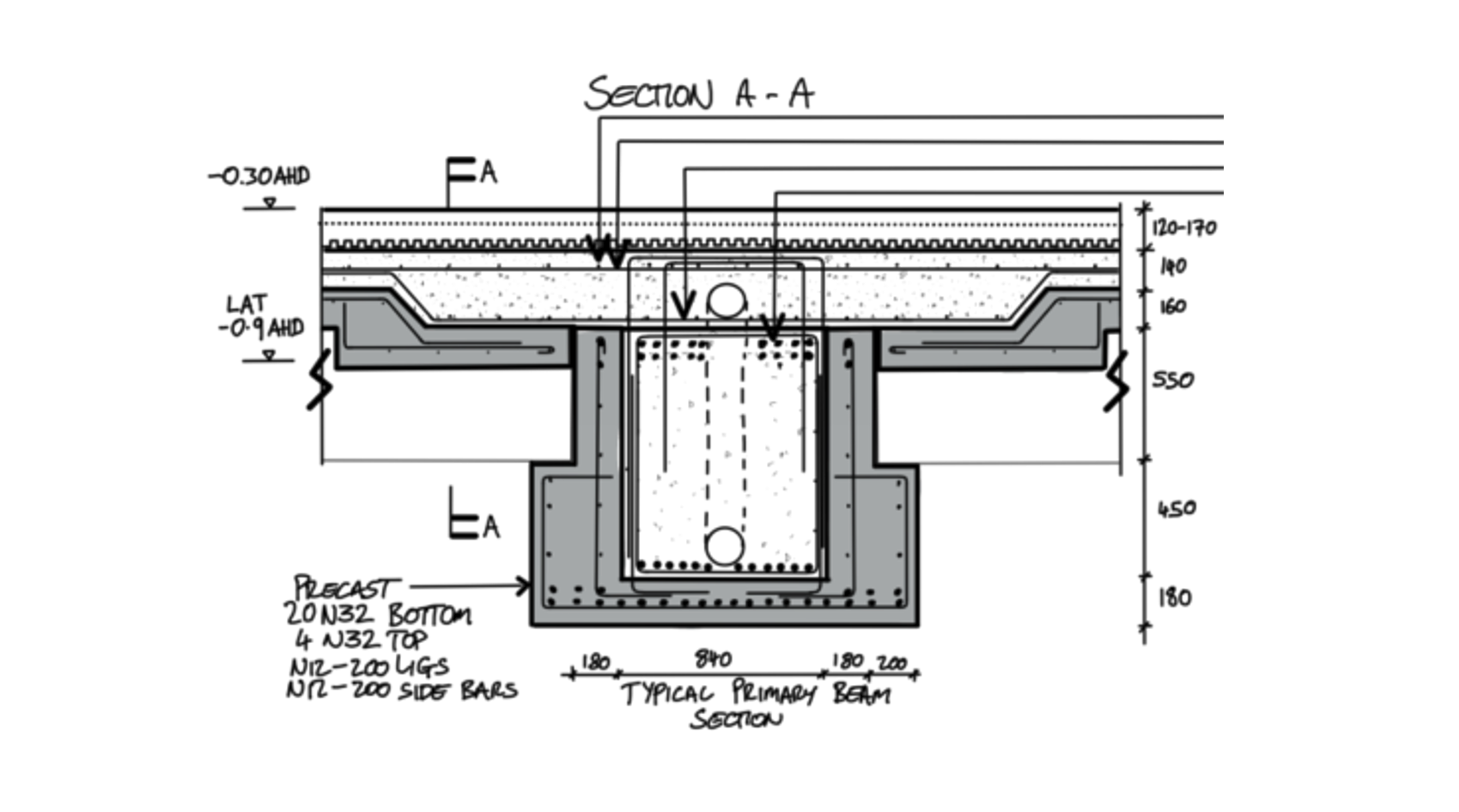

With the car park level situated below the waterline, the building needed to be designed to withstand tremendous hydrostatic pressure.

“Balancing the dead weight of the building and hydrostatic pressure that we get from the water was a key consideration,” Babcock said. “How deep you push the basement down increases the amount of hydrostatic pressure, which then means you have to either add more mass to the top of the building, or increase the length of the piles that are pinning the building down.”

In other words, what goes down is forced to come back up. By minimising the depth of the basement, the hydrostatic pressure is reduced and the length of the piles “holding down” the superstructure is minimised.

Design for manufacture and assembly (DfMA) and the use of precast concrete were essential to achieving this in the reference design, where only 10 different precast panel types were deployed across the entire 20,000 m2 space to create a permanent formwork placed just above the water level.

“DfMA has reduced how far we had to dewater the bay, and how many people we have operating in that marine environment,” Babcock said.

“Other options investigated included forming and jacking down large in situ areas of the basement before jointing and dewatering; or adopting floating steel forms jacked into position with in situ concrete poured on top, before being jacked down and reused in the next pour.”

A number of factors fed into the final decision not to adopt precast. Babcock said it came down to cost, capacity of the market and contractor preference.

“The precast market is constrained here in Sydney. The residential market dominates, and therefore the costs of producing a relatively small volume of discrete panels for a fish market proved disproportionately high.”

Innovating for maximum impact

A multimillion-dollar cofferdam and an innovative modular roof

made from timber complete the design.

In the early stages of construction, motorists and pedestrians alike were struck by an unusual sight.

An entire section of Blackwattle Bay was drained and a series of large steel piles driven into the ground, creating a vacant space below the waterline within a 400 m-long perimeter.

“Those piles are driven down to rock to cut the water off,” Babcock explained. “Within that cofferdam is a dry patch of seabed … that creates a safe, dry environment from which to build the building up.”

The cofferdam will soon be removed, he said, allowing water to flow back into the space it vacated.

“The building will start to feel this uplift pressure from the water, an hydrostatic pressure which will start to exert that upward force on the rest of the building. As the tide rises and falls, that pressure will change.

“The height of the ground plane was set by a tension created between maintaining a connection with the public at ground level, while catering for overland flow from Wentworth Park and rising sea levels due to climate change. Resilience is key when designing facilities for 50-100 years into the future.”

Fully modular

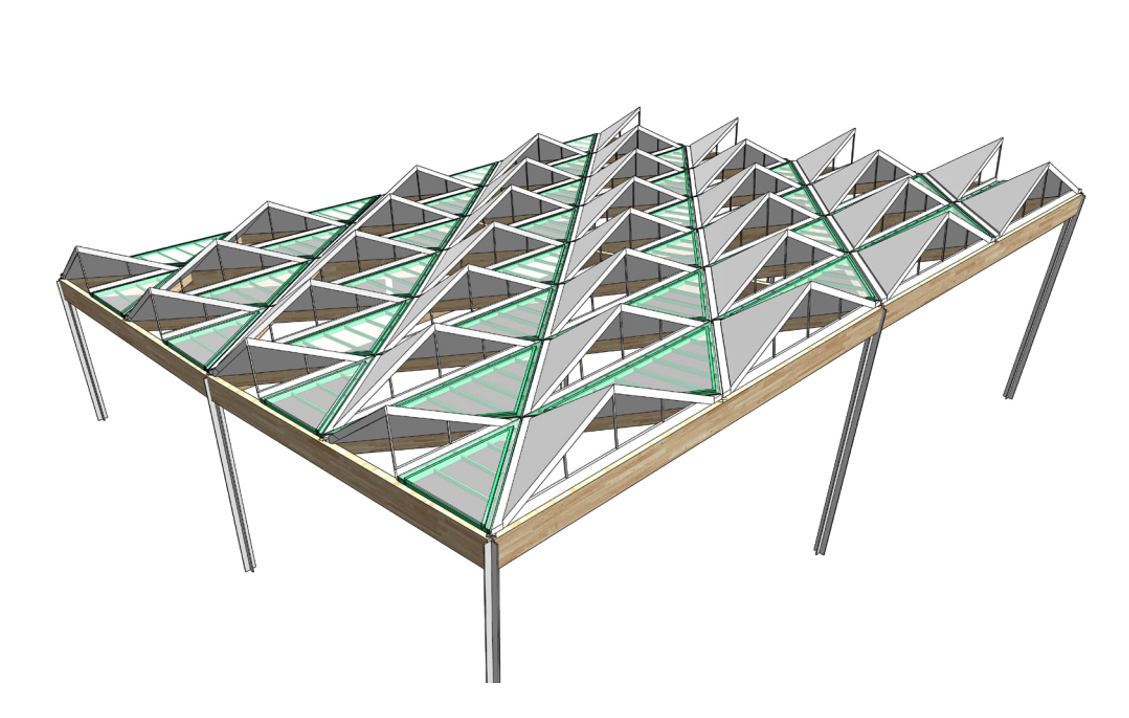

When the project draws to a close, expected to be in 2025, the market will be able to make an ambitious claim to fame.

“This is the largest timber roof in the southern hemisphere,” Babcock said. “There are buildings that have timber of this depth, but not of this scale.”

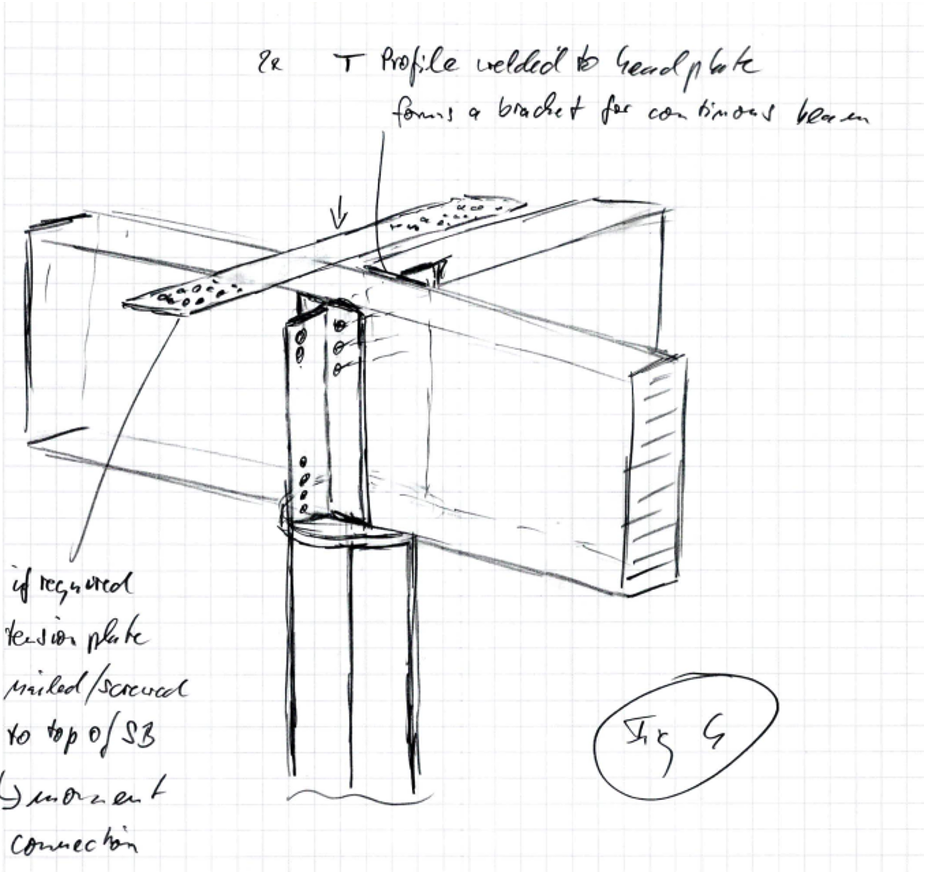

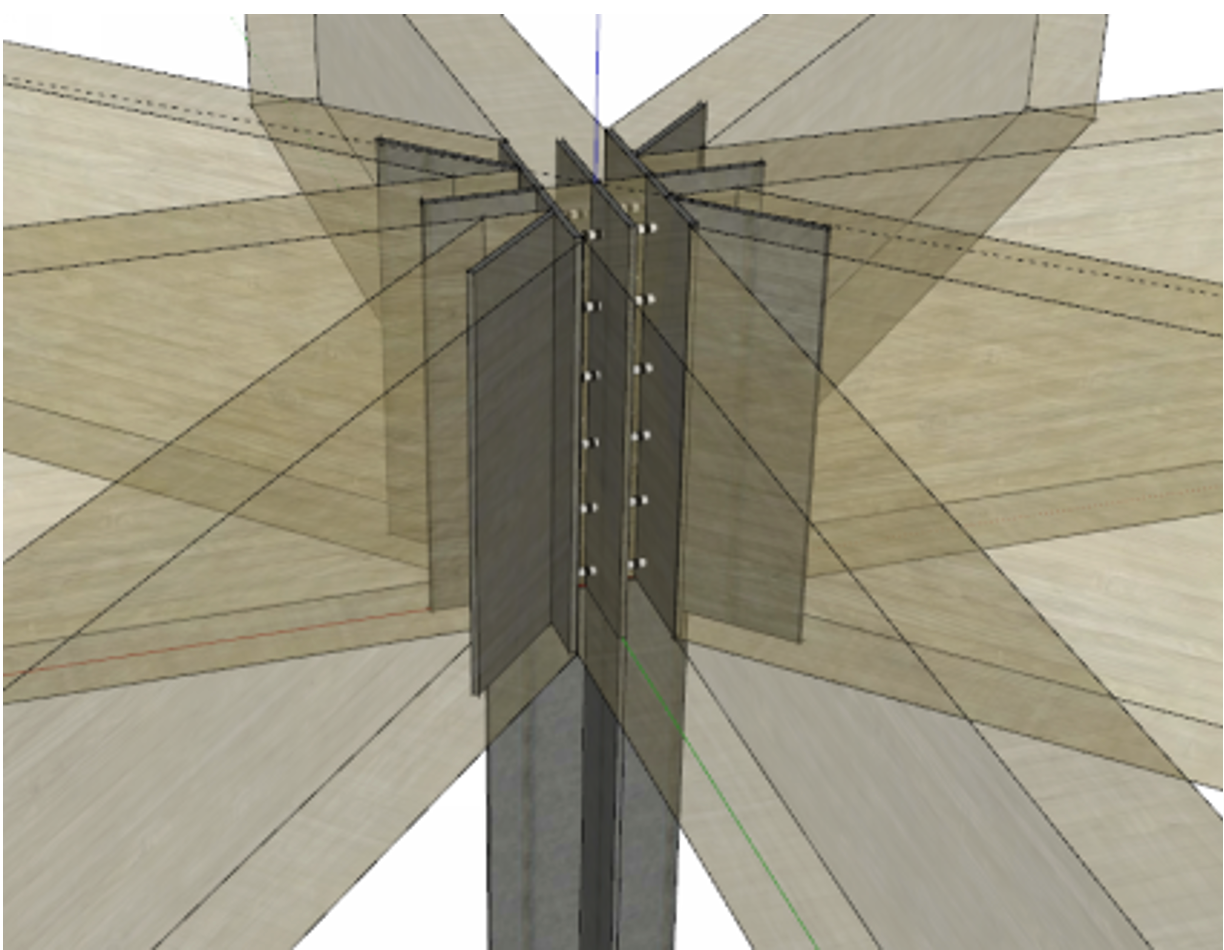

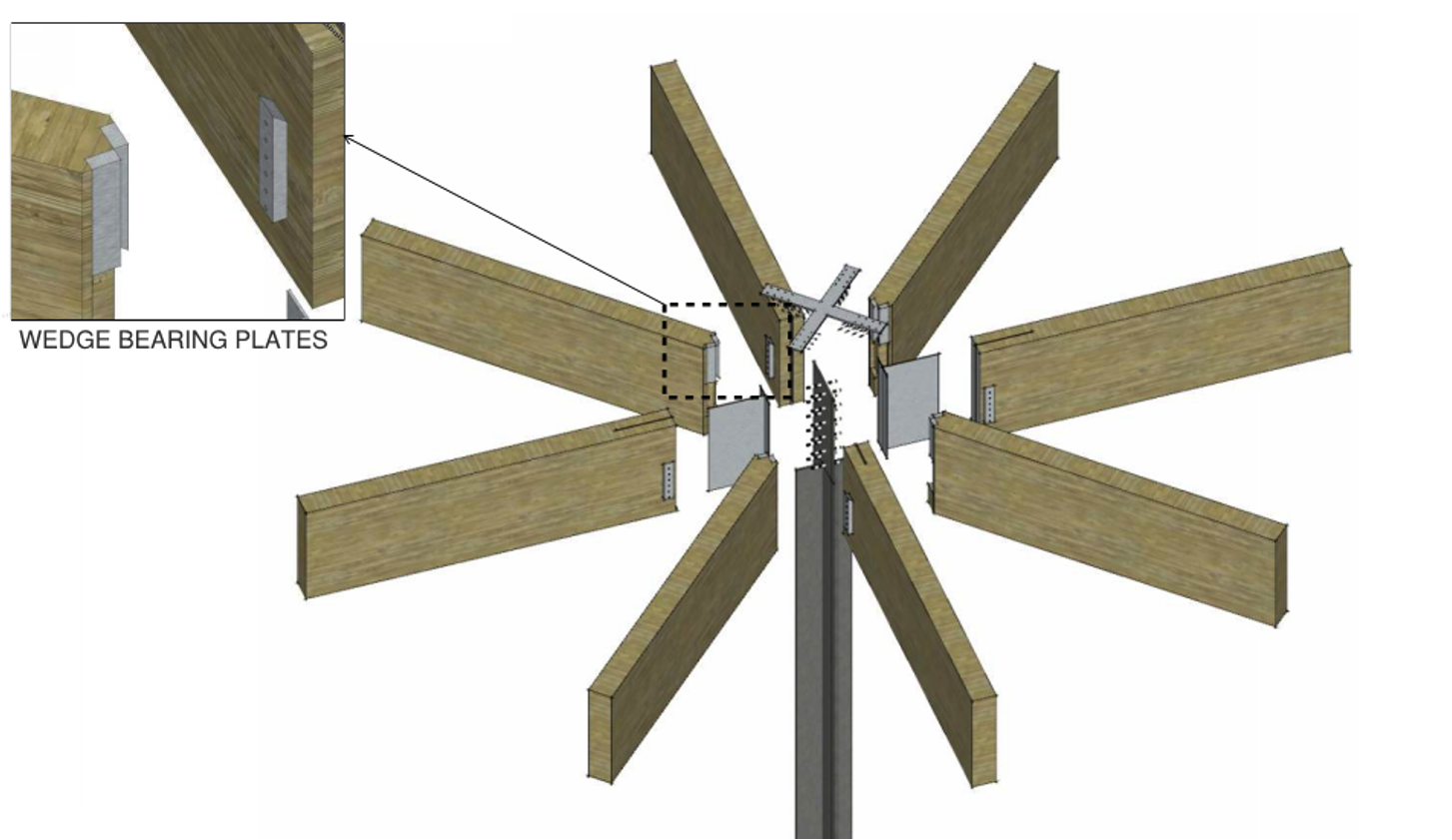

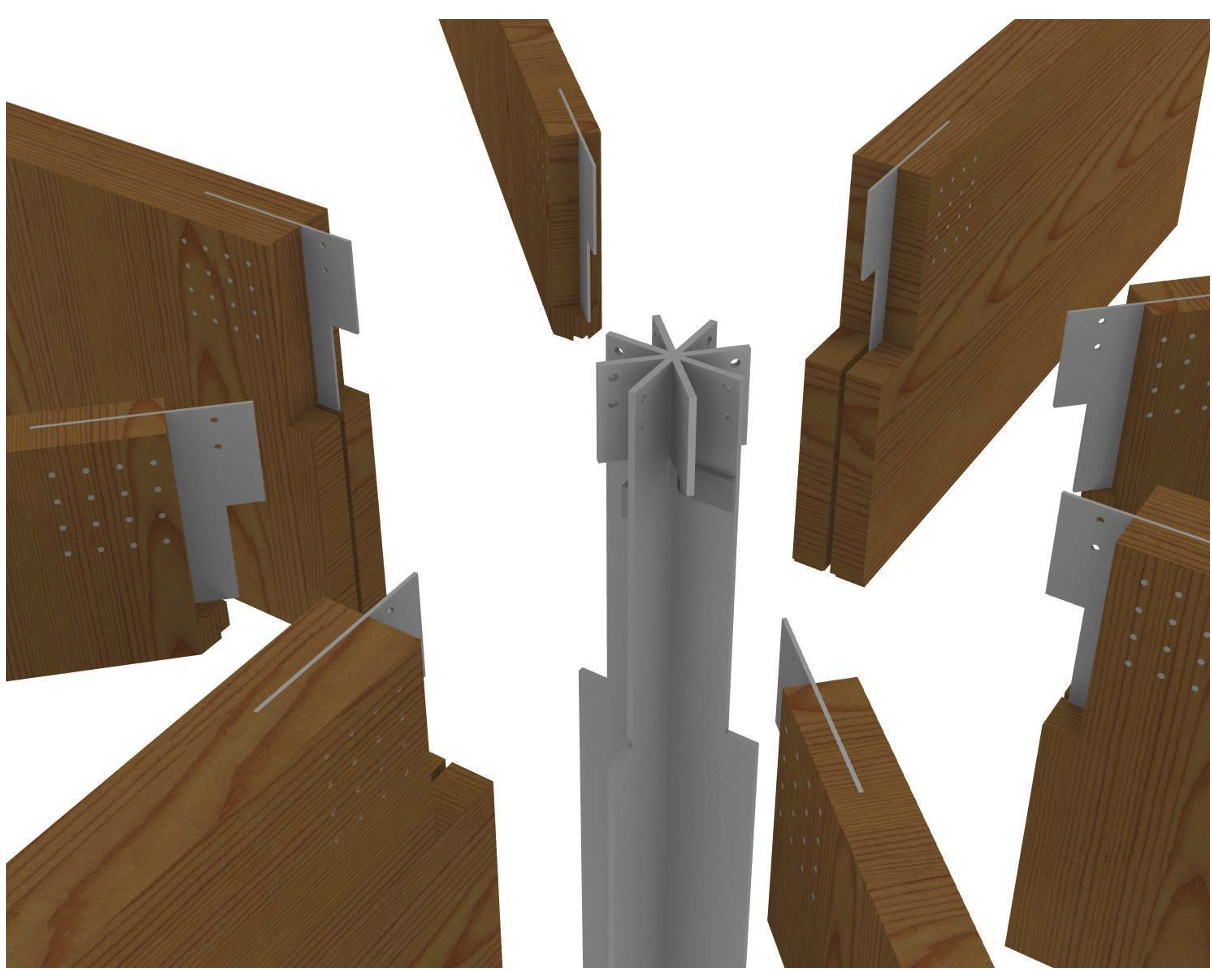

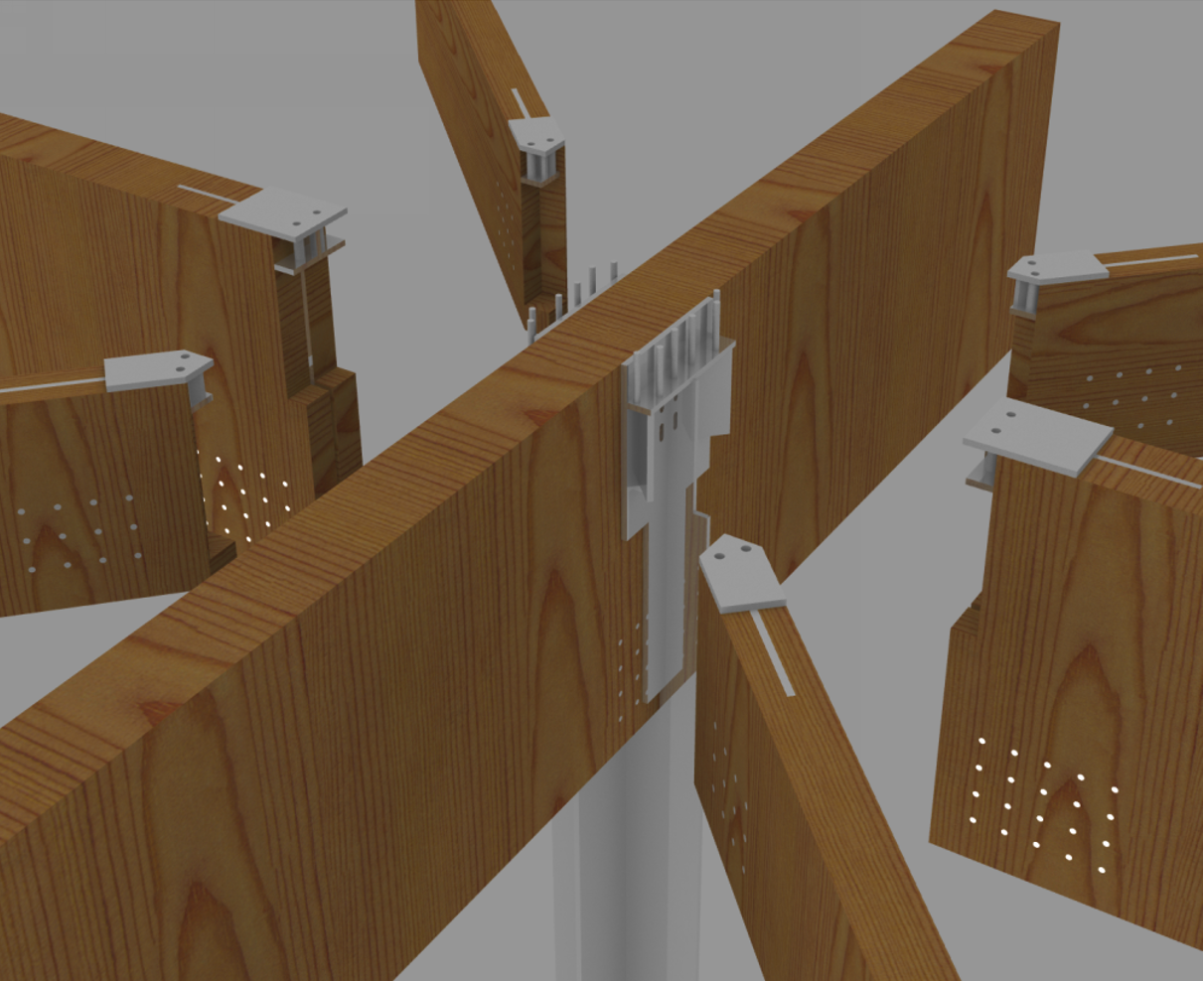

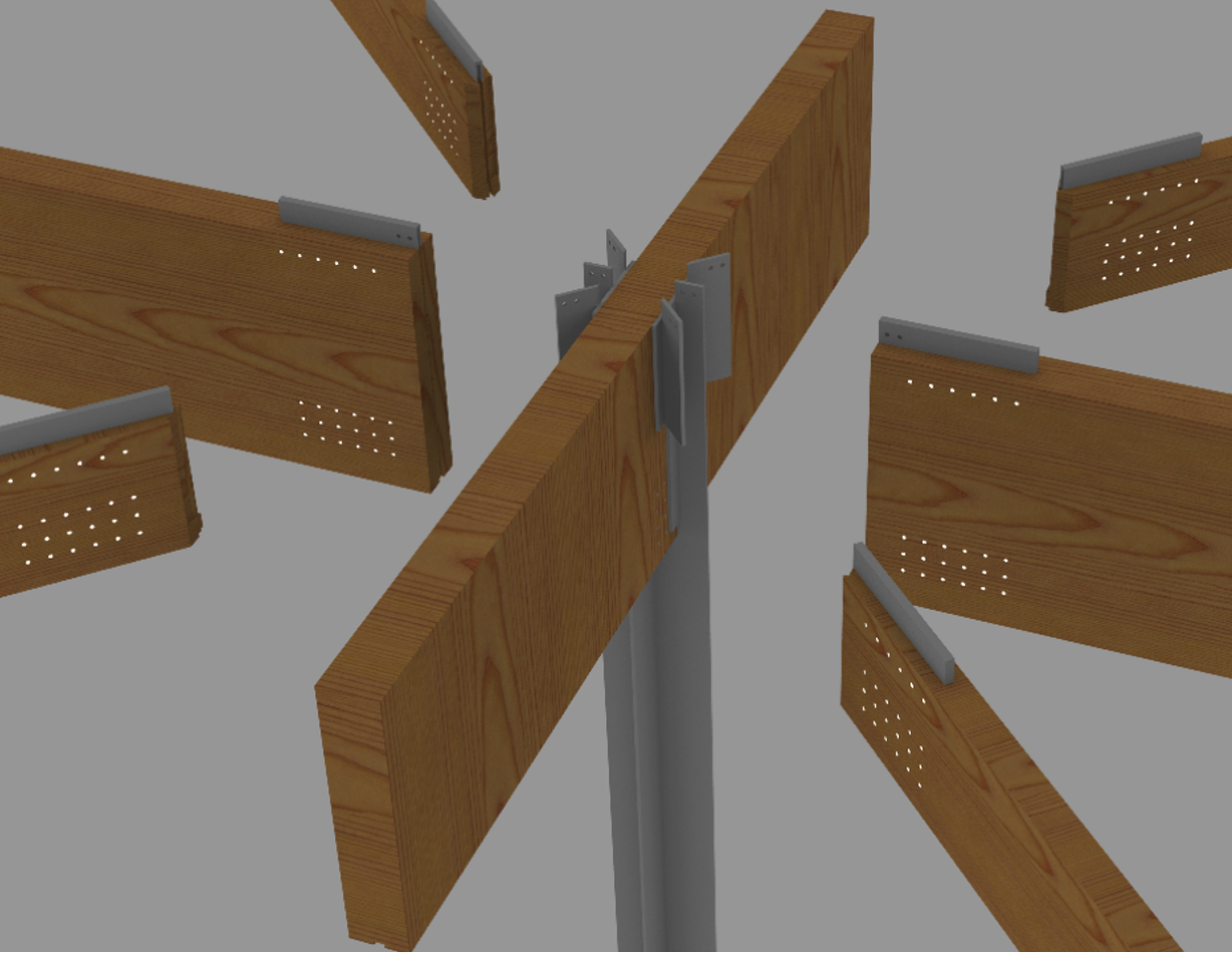

Beams up to 1.8 m in depth and spanning 30 m support the 400 roof pods across a total area of more than 200,000 m2. Up to eight beams connect at the cruciform column locations to create an undulating icon reflective of the surrounding marine environment.

“We looked at multiple roof options, including concrete steel, and a mixture of steel and timber, before deciding on a fully timber roof,” Babcock continued.

“This is an aggressive marine environment in which timber has a lot of advantages over steel: it doesn’t corrode, it performs really well for the loads that are imposed on it, and from a sustainability perspective there’s a huge amount of embodied carbon capture within the roof.”

The team even travelled to Europe to develop a better understanding of the supply chain, its capability and capacity, and production techniques.

“At the time, the Australian market actually would have needed to build a new plant in order to manufacture the beams. The European market is currently far more advanced in mass timber construction”.

Given the sloped nature of the roof, each of the 400-plus roof pods is oriented differently.

“No two roof pods are geometrically the same in terms of how they sit relative to the vertical and horizontal planes,” Babcock said. “One of the key moves there was to articulate the roof pod down its centreline to allow it to fold onto the roof, which means that we could, in conjunction with the roof pod connection, create a standardised design for every single pod.”

They could, therefore, be manufactured offsite before being dropped into place, maximising quality and safety.

Environmental emphasis

A lens was also taken to closing the market’s energy consumption loop year-round.

The new market is located on the south-east edge of Blackwattle Bay, which is ringed by the cycle paths and green spaces of surrounding suburbs Glebe and Pyrmont.

Despite its surface beauty, however, this specific area of the bay is notoriously limited in its fish population.

Working with a number of NSW universities, the team has augmented the design of the new market with 3D-printed coral elements intended to foster new marine habitats; these will be attached to the outside of the building that extends below water level.

Internally, a wide canvass of heating and cooling requirements are necessary, with the associated impact on the environment always needing thought.

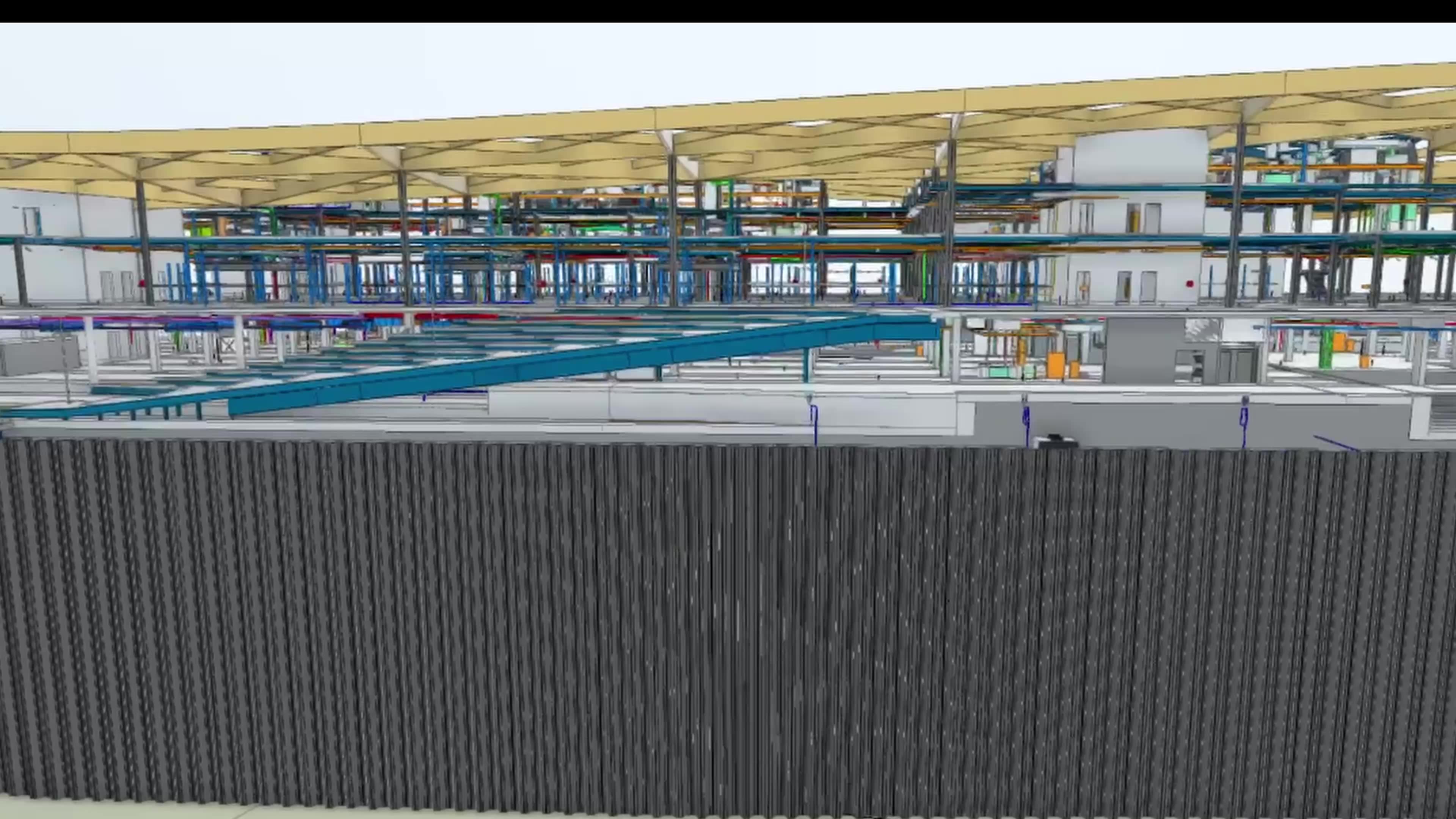

“In the building’s mezzanine, a very large central thermal energy plant serves all the cooling loads in the building, from chilled water to medium- and low-temperature loads,” Calcoen said. “Although not a conventional design, a multi-temperature central energy plant has a lot of benefits.

“The alternative would be to have lots of little cooling plants dotted around. Unfortunately, what happens with those systems is that they might have a life cycle of 10-15 years, and they are not as energy-efficient. With a centralised solution, we can look at a life cycle of 25-30 years.

“This was a key design move that was made early in the design and enabled a wide range of benefits to be unlocked around operational carbon, embodied carbon, spatial efficiency and easier integration into the architectural design.”

The plant’s energy recovery system is meant to close the loop as much as possible, which is helpful when considering heating needs during the colder months.

“While the heat is being drawn out of these various cooling processes, we're trying to redirect that – we've got some thermal storage in the building, where we're holding that heat so it can be reused for space heating, domestic hot water and defrosting.”

Image captions

Harvesting rainwater

Being an active fish market, the building will involve the washdown of facilities on a daily basis.

“In addition to harvesting all the rainwater coming on the roof, that washdown water actually has a separate catchment system that brings the water back to a centralised wastewater treatment plant,” Calcoen said.

The roof was designed to allow as much natural light through as possible. Image credit: Mott MacDonald

The roof was designed to allow as much natural light through as possible. Image credit: Mott MacDonald

He described this approach as unique for a project such as this.

“Generally you see that kind of solution on a precinct scale, but here it’s within a single building. We’re capturing all that water, treating it and then reusing that throughout the building – including in the cooling towers, which are part of the central thermal energy system, alongside irrigation and other uses.”

Calcoen summarised the new market as being far from a traditional retail building.

“When you walk into a traditional shopping centre, you walk into a controlled, enclosed space,” he said. “The market is an open market hall. This comes with challenges that must be overcome, but also advantages; we aren’t air conditioning every single corner, which has energy efficiency benefits while also fostering a connection between inner and outer spaces.”

Here, as it has throughout the course of the project, the building’s civic purpose was made a priority.

“In the construction industry, we talk about base build designs, integrated fit-outs and how to bring people into a building,” Calcoen said. “Because ultimately that’s what buildings are for: they’re here for people.”

More from create

If you liked this story, find similar explorations of design and engineering innovation below:

Infographic: Constructing Parramatta Light Rail

Discover how engineers reduced carbon dioxide output by more than 4800 t on another major Sydney construction project.

Video: The artificial reef boosting biodiversity

A Melbourne company has installed an artificial reef that reduces coastal erosion while maximising protective space for marine life.

Article: Three sustainable timber innovations

These four projects reimagine timber’s role in construction, including through the use of densified wood and fibre-reinforced polymer.