From the tallest buildings ...

... to subterranean caverns.

The most turbulent oceans ...

... to the depths of space.

Extreme engineering enables human exploration.

To realise new materials and technologies, engineers are …

By Cris Andrews, Joseph Harding and Lachlan Haycock

Engineers have always pushed the boundaries of what’s possible. Since the industrial revolution, this drive to innovate has taken us from the steam engine to sending probes to the centre of the solar system.

But this drive is tempered by risk. And it takes a special kind of engineer to build something that can withstand the sun’s heat, the pressures of the deep ocean or hold the weight of a skyscraper.

In Singapore, the authorities encourage underground construction to free up living space on the surface. The country has one of the world’s highest population densities – 8177 people per km2, around 200 times as dense as the USA and 2000 times that of Australia. The global average population density is 63 people per km2.

Sreekanth APV, Global Operations Director – Workplaces at Arcadis, was Head of Design Engineering when the company worked on Singapore’s deep tunnel sewerage system.

“In Singapore, roads, rail networks, parking and recycling facilities have all been built underground, as has a cooling system and water reclamation system,” he said. “The country’s Land Use Plan 2030 designates surface space for housing, community facilities and offices. Authorities want to move more industry, transport infrastructure and retail below ground.”

Sreekanth added that, when managing risk for underground construction, engineers work out what kind of facilities need to go underground, before investigating soil behaviour, drainage and hydrological elements.

“You then consider how underground constructions impact the surroundings above and below ground, particularly in urban areas.”

With its population rising and surface space running out, Singapore’s government has outlined a master plan to take advantage of underground spaces.

Let's take at look at some of the subterranean ideas being explored.

The long-delayed Bidadari Bus Interchange, which is located underground in the island's heartland suburbs, finally opened earlier this year, keeping more vehicles off the streets.

Meanwhile, electrical substations can be placed underground and serviced through select access points. These access points would occupy only a small amount of space on ground level, keeping the bulk of operations out of sight.

Underground pedestrian links can facilitate connects between buildings and beneath busy roads.

In 2019, Singapore briefly explored a program to build bicycle storage stations below the surface. Although this failed due to low demand, the initiative exhibits the country's penchant for below-ground exploration.

In the Marina Bay district, certain facilities are housed in a common services tunnel. An underground district cooling system centralises the production of chilled water.

In 2024, residents in Yuhua trialled the Pneumatic Waste Conveyance System, which uses a vacuum-type pipe network to collect household waste.

Removing road and rail networks from the surface can help to ease congestion and enhance above-ground living spaces.

Take, for instance, the under-planning Cross Island Line, which will expand the MRT network with more than 50 km of new rail, all of it underground.

The Deep Tunnel Sewerage System, 100s of kilometres long, has been termed a "massive underground superhighway" for wastewater management.

An extensive network of tunnels funnel used water to three centralised water reclamation plants in Changi, Kranji and Tuas, the extreme east, north and west of the island.

The Jurong Rock Caverns are designed to store liquid hydrochemicals beneath Jurong Island, southwest of the main island, saving an estimated 60 ha of land. Its estimated capacity is 1.47 million m3.

Singapore has even stored ammunition below-ground. Rock caverns beneath the old Mandai Quarry were converted into the first such storage facility, a process that took 10 years to complete.

The country's first underground service reservoir has been completed beneath Bidadari Park – not far from the underground bus interchange. Twin chambers are located at a depth of 6.5 m. Up to 9000 households are expected to benefit by the third quarter of 2025.

Although far from the only country with eyes on expanding underground, Singapore has built an impressive track record in its efforts to make the most of a finite resource: land.

Building up

Andrew Johnson, Arup Principal and Structures Leader for NSW and ACT, has designed tall buildings across Australia, the UK, the US, Asia and the Middle East for 23 years. He’s worked on China Central Television Headquarters in Beijing, Marina Bay Sands in Singapore, North and South Tower in Bogota, Columbia, and 1 Blight Street and Salesforce Tower in Sydney.

Johnson said tall buildings must be built to withstand a variety of complex lateral and vertical forces.

“These come from the site, its environment and from the building’s own sheer weight,” he told create. “Most often, that’s the wind climate and how it interacts with the building, but in places like Beijing and Singapore you also need to consider seismic activity. Singapore is near the equator, so wind speeds are low, but there’s a risk of the area being affected by earthquakes.”

To predict a tall building’s performance, Johnson puts a 1-400 scale model in a wind tunnel and uses digital modelling technologies to build a picture of the wind terrain.

“We use a simulation of the building’s structural performance to predict the response and performance under the loading events, then design the structural elements such as columns, walls, bracing, beams, slabs and foundations. From this, we discover the wind load and where the concrete might crack.

“This helps us understand forces and elements, gravity and earthquake loads. The model includes the new building, in situ, with what’s already there.

“Surrounding buildings cause wind to move in different ways. For instance, the wind blowing across Sydney Harbour towards Salesforce Tower hits buildings in front and causes turbulence but may also shield the new building.”

Dr Adam Jan Sadowski, of Imperial College London, is designing computer simulations to better understand the performance of offshore wind turbine support towers.

“The aim is to build precise digital twins of wind-turbine support structures, enabling safer and more resilient designs while minimising unnecessary material use and related cost,” Sadowski said. “By offering more precise, data-driven assessments of structural and safety requirements, digital twins can identify opportunities to reduce both overdesign and excessive use of steel.”

Looking down on the skyscrapers of Dubai from the Burj Khalifa. Image: Unsplash

Looking down on the skyscrapers of Dubai from the Burj Khalifa. Image: Unsplash

Understanding both the underground environment and the surface is equally important when designing tall buildings, according to Andrew Johnson.

“In Sydney and Manhattan, where the surface is solid rock, you can use a raft to carry the vertical load and distribute the forces into the ground,” he said. “Where the ground is softer, say in London, you need 15-30 m-long piles to get through the soft clay and into the deeper chalk layer.

“But for China Central Television Headquarters in Beijing and Marina Bay Sands in Singapore – places where you can’t get through to rock and the loads are too high for piles only – we used a pile assisted raft, which is a hybrid system. The piles provide extra support, and the raft distributes loads across a wide area of ground. With tall buildings, you don’t want any concentrated loads.”

Johnson knows firsthand what can happen if the ground investigation is incomplete.

“In the early 2000s, we were working in Doha and hadn’t finished designing the building when the client and contractor starts putting piles in the ground. We were still deciding how tall the building would be and they were pouring concrete into a pile, which didn’t fill up. It turned out the concrete was disappearing into a limestone cave under the site, which no one knew about because we hadn’t finished the site analysis.”

Africa’s tallest building

The Iconic Tower is the centrepiece of Egypt’s New Administrative Capital, outside Cairo. Unlike many skyscrapers built in desert conditions, which are supported by piles driven into the bedrock, this project had no accessible shallow bedrock.

To get around the unstable ground, Africa’s tallest skyscraper is built atop a 5 m thick concrete raft. Beneath this raft, piles are still used to compact the layers beneath, mimicking the function of a bedrock anchor by compressing the soil and spreading the load evenly.

Consisting of 18,500 m3 of concrete, the slab was poured over a continuous 48-hour period. Engineers used real-time thermal monitoring and concrete cooling systems to control the heat generated during curing, helping to reduce the risk of cracking due to thermal stresses.

Fine line

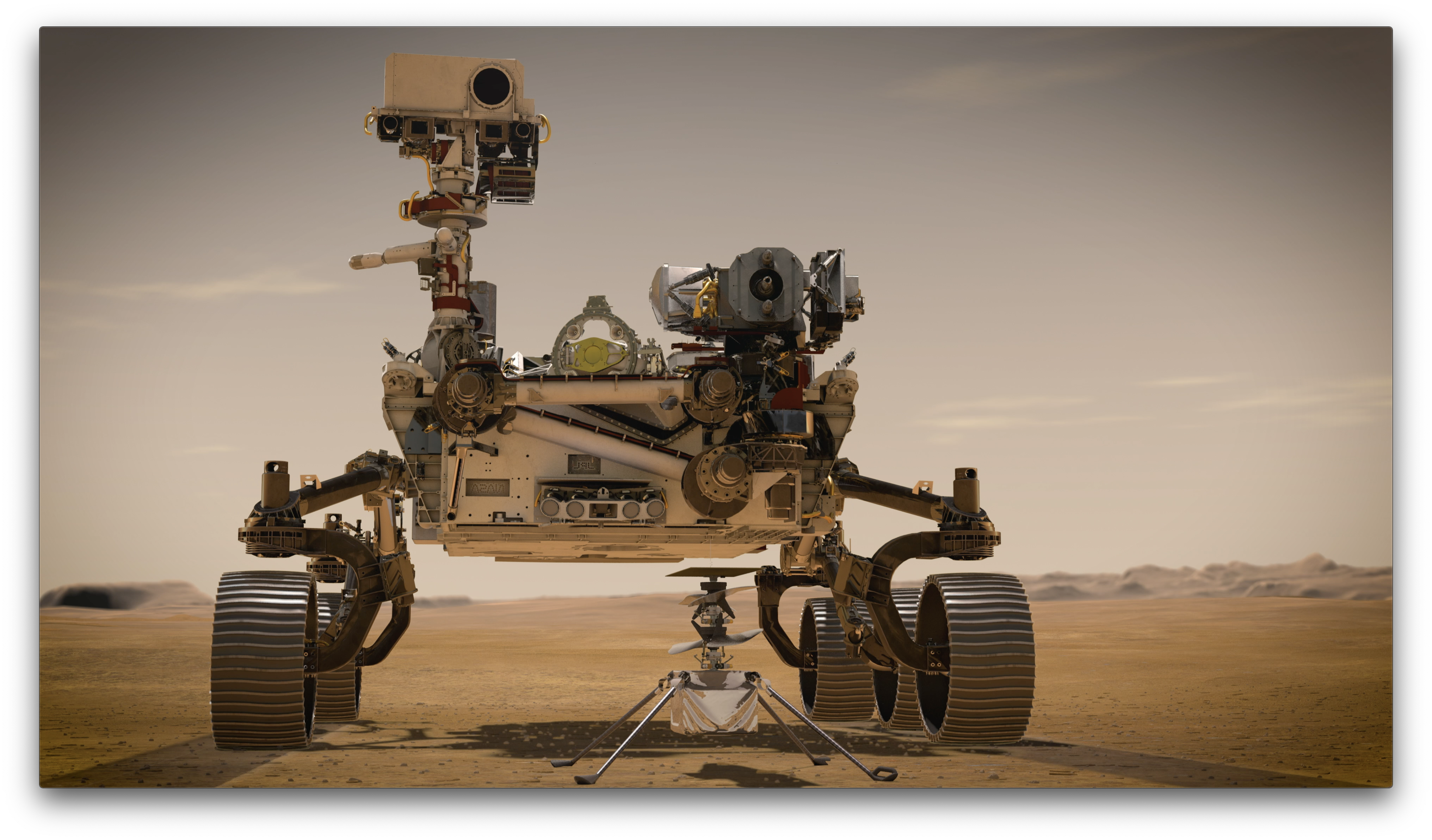

Engineers designing technologies for deep space must contend with a wide variety of extreme conditions. Carlos Bacigalupo, Head of Engineering at the Maxon Group, a company that has designed motors for use on solar orbiting and Mars exploration vehicles, explained.

“Our motors must withstand shock and vibration during launch, and massive temperature extremes during the journey,” Baciagalupo told create. “Components must withstand radiation which, depending on the radiation’s frequency and wavelength, can cause ultraviolet damage, dry out anything on the motor that has the capacity to evaporate, and affect electrical components and soldering.

“There is also ionisation to think about, which creates static currents that can attach to, and corrode, metals.”

Bacigalupo said the Maxon motor sits idle for a long time, but must do its job at a very specific point.

“There’s a protective shield in front of the instruments on the vehicle that needs to be exposed to the radiation to do the measurements, but remain shut to protect the instruments during the rest of the journey. When the vehicle is in the right place to do its analysis, the motors kick in and move this shield. If the motor doesn’t respond for any reason, the mission fails.”

Maxon motors also contain pairs of sensors, specially hardened electronics to reinforce the drives, laser welding between components, and special brushes impregnated with a lubricant and silver graphite.

“It’s impossible to design for redundancy on the motor itself, there’s no second circuit,” Bacigalupo said. “But there are non-critical parts of the motor that can fail, and the motor still performs.”

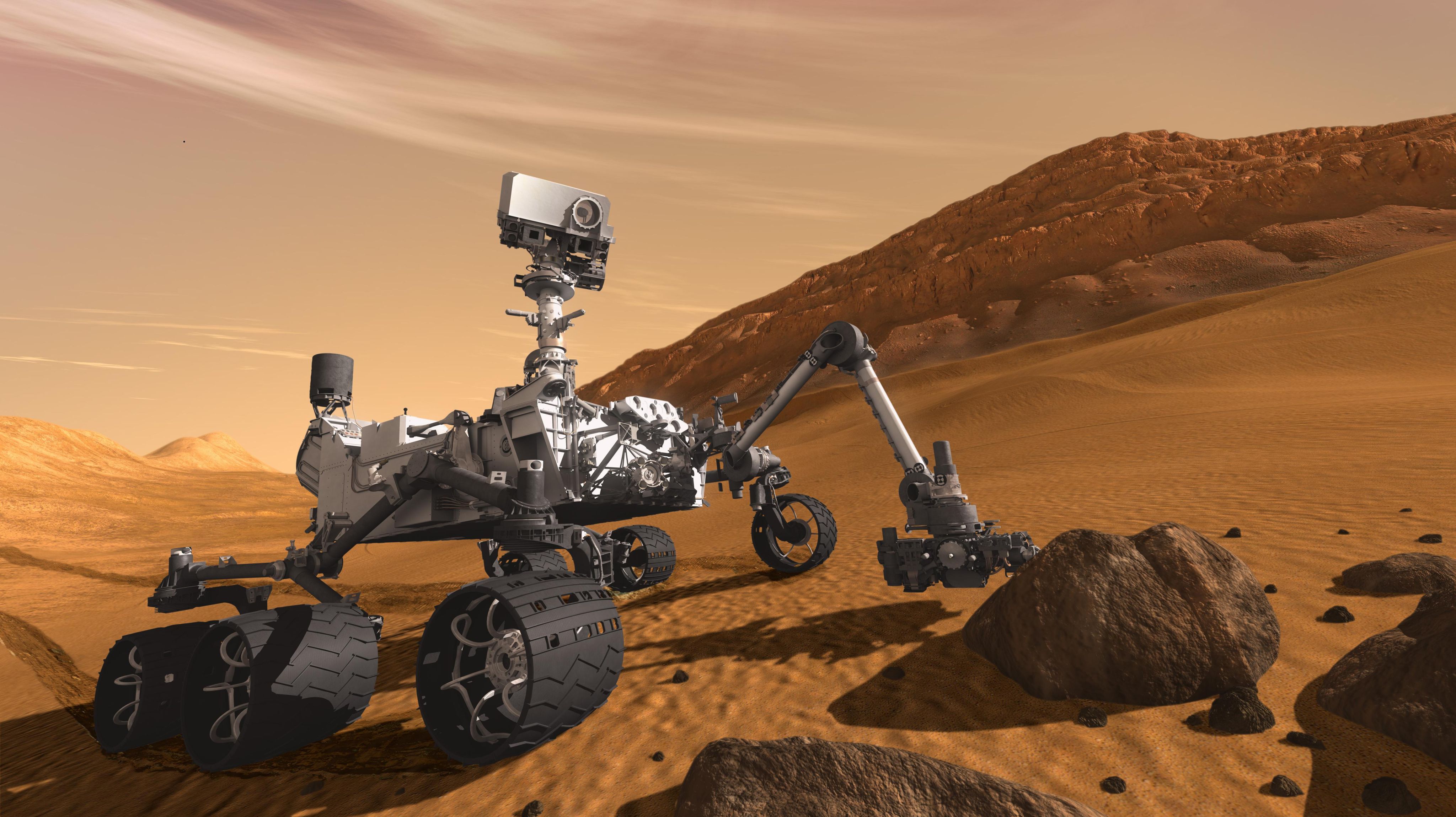

NASA's Curiosity Rover.

NASA's Curiosity Rover.

Heatproof componentry

Resilient materials are essential if engineers are to effectively manage risk when designing technologies for space travel. Researchers at Japan’s Tohoku University have created a titanium- and aluminium-based alloy that can retain elasticity in temperatures as high as 127°C and as low as -269°C.

“Currently, most shape-memory alloy materials capable of regaining their original shape after force is removed are limited to specific temperature ranges,” Sheng Xu, a Tohoku University engineering professor involved with the project, said.

The Tohoku research team employed advanced techniques such as rational alloy design and precise microstructure control. By using phase diagrams, the researchers were able to select the right alloy components and their proportions. “We optimised processing and heat treatment methods to achieve the desired material properties.”

Similarly, engineers at the University of Pennsylvania believe that their new heat-resistant memory device could enable computers to operate in space, nuclear plants and other extreme environments in which traditional silicon-based transistors degrade.

The new ferroelectric diode – a semiconductor switching device – uses a material called ferroelectric aluminium scandium. The researchers claim this material is thick enough to prevent the material degrading, but thin enough to facilitate ferroelectric switching.

Ferroelectric switching is the process of changing the polarisation of a material by applying an electric field. Ferroelectric materials don’t need continuous power to retain polarisation states and can be relied on to store data in high temperatures and radiation environments. As a result, real-time monitoring and maintenance improves, minimising risk of data loss, equipment failure and system malfunction.

“Today, there is no reliable way to store information electronically at temperatures over 300°C,” Professor Deep Jariwala, Associate Professor of Electrical and Systems Engineering at the University of Pennsylvania, told create. “If the sensor is designed to survive these temperatures, the data it captures must be either transported to a colder environment for storage, or stored reliably in that hot environment for instantaneous processing and feedback control.

“Our ferroelectric diode technology helps solve this problem by reliably co-locating the data storage to the location of the data collection. A memory that can store data indefinitely in such instances without need of any external power is critical in case of sudden power outage.”

The Ghost Shark, Anduril Industries.

The Ghost Shark, Anduril Industries.

Subsea pressures

According to Scott Wade, Professor of Engineering at Swinburne University of Technology, componentry, particularly the hydraulics, in submersible vehicles must be super resilient to avoid the potentially disastrous consequences of the technology breaking down, as seen in the Titan submersible incident.

“Marine hydraulics perform critical functions – assisting stabilisers, steering and propulsion. These can suffer damage, though, and in worse-case scenarios fail because of corrosion and marine biofouling.

Wade has been involved in designing thermal coatings to protect marine hydraulics. “Our coatings, sprayed with high-velocity oxygen fuel, work against both issues.”

This thermal spray is made from powdered metals and other compounds known for their durable and protective properties – tungsten carbide, nickel and cobalt chrome. The spray is applied by a giant flamethrower that creates high temperatures and speeds – roughly 2,000°C at 800 m/s. This combination of heat and speed produces dense coating layers that have few air gaps between the particles, making sea water unlikely to enter and cause corrosion.

“The spray hits the surface and solidifies, creating an extremely well-adhered coating,” Wade said. “Thermal spray techniques can also add metal coatings to glass and carbon fibre composites for greater resilience.”

Anything is possible

Extreme environments provide another challenge for engineers. In some remote places, the data needed to inform engineering decisions is not always available.

“In a desert where there has never been any development, you start from scratch,” Johnson said. “We’ve had sites where we’ve had to move buildings because it turned out the ground was not strong enough for a building of that size.

“In Bogota, Colombia, we had to develop our own wind profile for the site and the surrounding hilly areas, to use in the wind tunnel.”

According to Bacigalupo, engineers working in extreme environments must assume that anything and everything is possible.

“If you can imagine a potential scenario, you can’t assume that it won’t happen. The scenario must be addressed, or at least imagined as a possibility.”

There are plenty of challenges, but the good news from Bacigalupo is that engineers don’t have to work on them all at the same time. “That’s the benefit of a systematic approach. You can address challenges separately; the most important thing is that everything is working at the end.”

Explore the extreme engineering of tunnelling into the earth at the Australasian Tunnelling Conference, taking place in Perth in November.

More from create

Continue reading with these other great stories:

Rethinking risk in major construction projects

Risk is integral to all engineering, but rarely are the stakes higher than on large infrastructure projects.

Why this Singaporean MRT station collapsed

Digging deep can sometimes lead to disaster, as engineers discovered on 20 April 2004.

Why Australia can't afford to stay out of space

Space is hard, but innovation in response to a challenge is what gives this country an edge.

![[Free Download] Whitepaper: the case for plastic corrugated stormwater pipes](https://createdigital.org.au/wp-content/uploads/2000/05/Plastic-pipes-75x75.jpg)