The modern world is built of steel.

And building a more sustainable world will require even more.

But steel has a major

emissions problem.

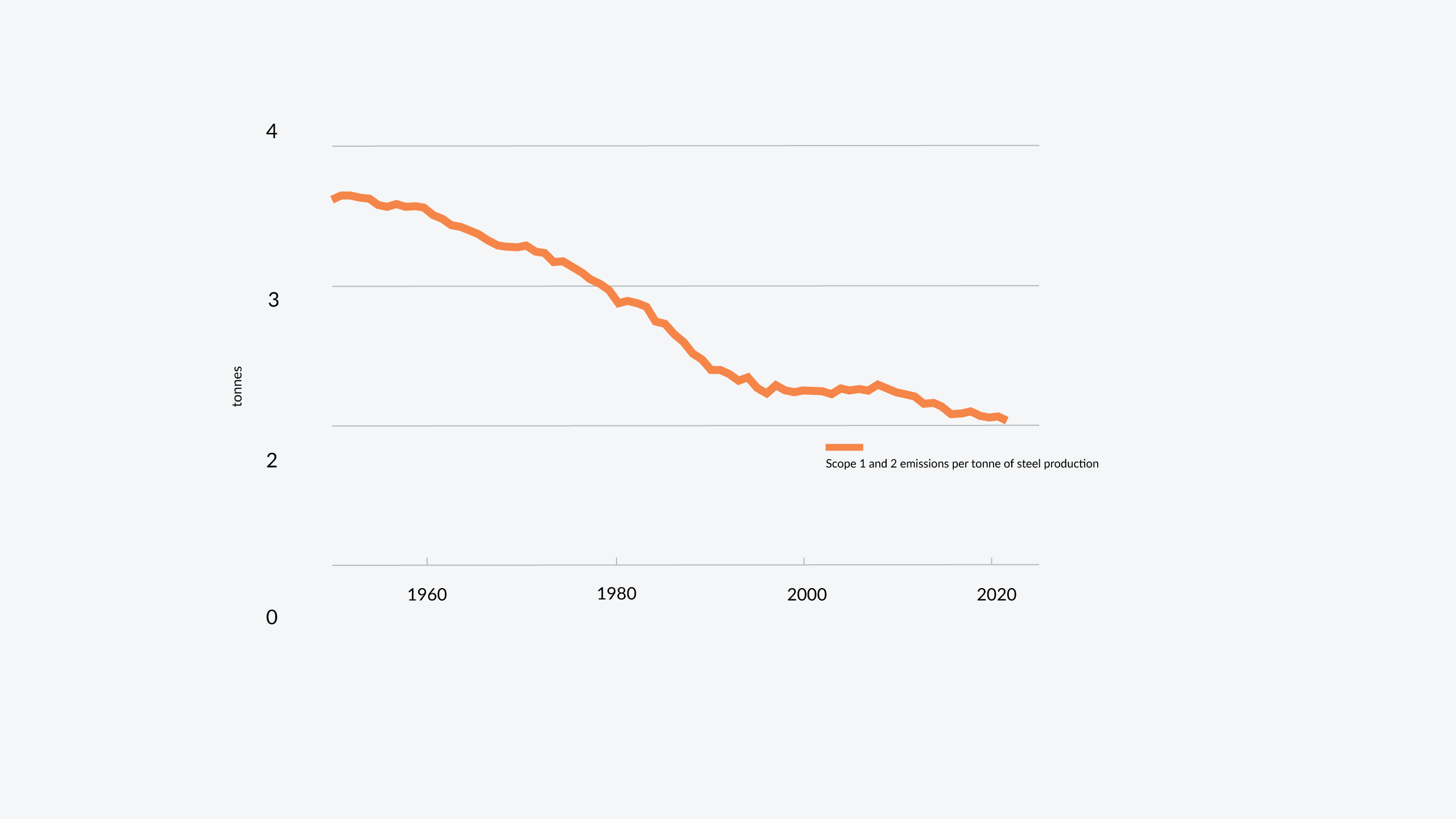

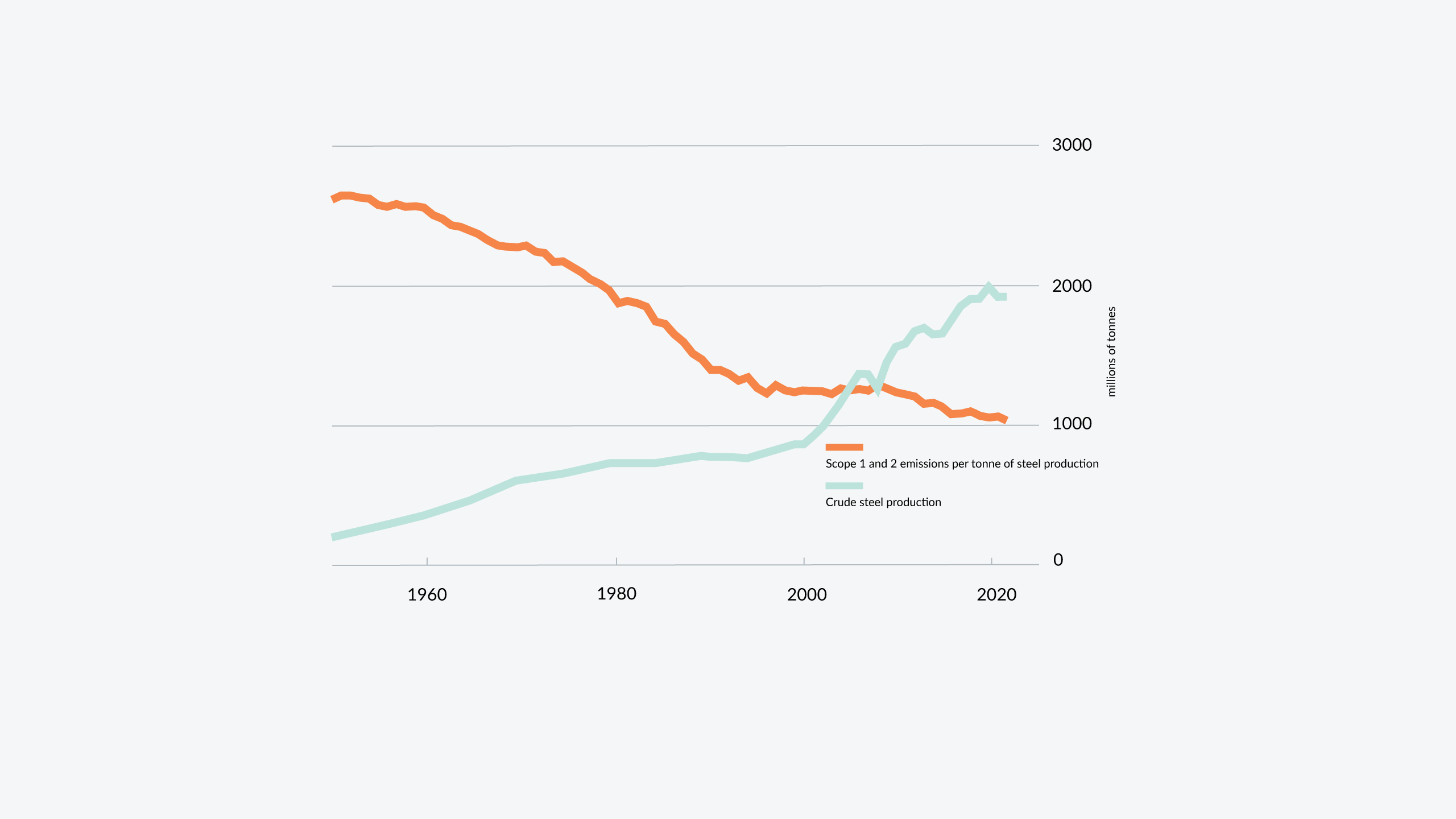

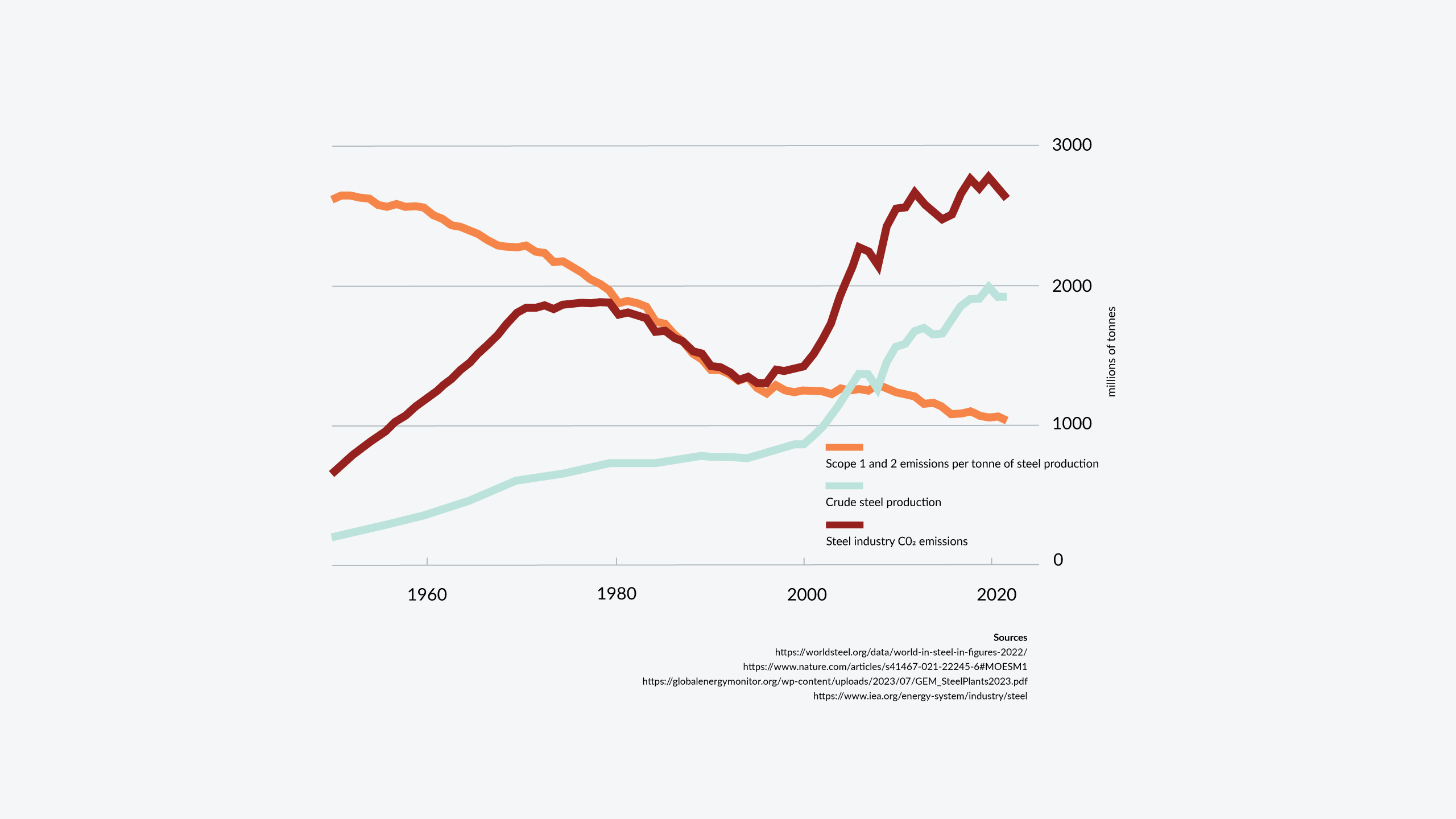

Over the second half of last century, numerous innovations massively improved the efficiency of steelmaking.

But progress on efficiency has significantly slowed in recent decades, while demand for steel has soared.

This boom in demand means that overall emissions from steel production have grown enormously. It is now the most carbon-intensive industry, accounting for an estimated 11 per cent of global carbon emissions.

But the vast amounts of infrastructure that are needed to build a more sustainable world are set to drive demand for the dirtiest material to unparalleled heights.

This makes decarbonising steel production a crucial enabler of the transition to sustainability.

And of all countries, Australia could have a disproportionately important role to play in this vital process.

By Oliver Gordon, Heath Dunn and Joseph Harding

Much of today’s steel does not come into existence without Australian iron ore and metallurgical coal.

More than one third of all iron ore is mined here, and we're also the largest exporters of metallurgical coal. In fact, converting Australia’s iron ore into steel emits more than 1.5 billion t of CO2 a year – triple the country’s domestic emissions.

With its abundant iron ore reserves, vast renewable energy potential and acclaimed engineering workforce, Australia has the potential to become a global leader in green steel, helping global industry decarbonise while transforming its economy in the process. Indeed, with the recent Future Made in Australia initiative, the Federal government has left no doubt about the importance of sovereign manufacturing capabilities to the country’s green future.

That future, however, is far from assured and there remain structural impediments to Australia’s green steel metamorphosis; both its government and industry must act fast and expediently to ensure the opportunity does not pass them by.

The global steel industry currently produces approximately 1885 Mtpa, with each tonne requiring around 1.6 t of iron ore to produce, and emitting around 1.9 t of CO2. As demand for steel rises in the future, particularly from Africa, and the industry fails to decarbonise as rapidly as other sectors like power production and transportation, the sector share of GHG emissions is forecast to increase.

“While some of the extra demand will be met through recycling, the current rates of raw iron ore production will need to be maintained or increase into the future to meet the increased demand for steel,” said Dr Stuart Walsh, a senior lecturer in resources engineering at Monash University.

Emissions from steel must drop by 50 per cent by 2050, and then continue to decline, to hit climate targets, according to the International Energy Agency. At the same time, steel demand is expected to rise by a third over the same time period.

“So we’re moving into a world that needs less emissions, but more steel,” said Dr Marcus Haynes, module leader of Lithospheric Geophysics and Economic Fairways at Geoscience Australia. “Our ability to produce green steel cheaply will play a significant role in meeting global ambitions towards decarbonisation.”

To meet global energy and climate goals, emissions from the steel industry must fall by at least 50 per cent by 2050, even as steel demand continues to rise.

Mining

Both iron ore and metallurgical coal must be mined to make steel under today's dominant production methods. Emissions from mining, beneficiation and material transport are estimated to produce about 600 kg of CO2E per ton of steel.

Electrifying mines is crucial to reducing these emissions.

Agglomeration

Iron ore particles are agglomerated into either pellets or sinter, traditionally via coal- or coke-fired processes. On average, sintering consumes roughly three times the energy of pelletising, though sintering often makes greater re-use of waste products.

Much research is focused on decarbonising these processes. Biomass has been successfully used to pelletise iron ore fines on an industrial scale, while CSIRO is working on a pelletisation process that operates at around 300°C, more than five times lower than the dominant approaches.

Sintering approaches using hydrogen and even solar thermal power in place of fossil fuels are also in development.

Ironmaking

Most iron is made via blast furnace, using coke and temperatures of around 2000°C to produce pig iron.

The leading alternative is direct reduction to produce sponge iron, which typically requires less refining for steelmaking.

Most direct reduced iron is made using a mixture of H2 and CO syngas made from either natural gas or coal, but hydrogen-based processes are gaining ground as renewable energy becomes cheaper.

Steelmaking

Approximately three-quarters of all steel is produced in coke-burning basic oxygen furnaces. With current production methods, the blast furnace–basic oxygen furnace process emits 2.2 t of CO2E per tonne of crude steel.

In place of coke, electric arc furnaces use electricity to heat iron above 1000°C to drive off impurities. The use of renewable energy here can dramatically cut emissions, but the process is not compatible with pig iron, instead requiring sponge iron or recycled steel scrap.

Casting and milling

Approximately 90 per cent of steel produced in modern mills is continuously cast, producing slabs, blooms or billets of steel. This is generally a less emissions-intensive method than ingot casting, the previous dominant method.

Once cast, the steel can be milled.

Use and recycling

The shift to renewable energy is helping drive demand for steel, with energy generation sources such as wind power requiring significantly more steel than coal or gas power plants for a given amount of electricity production.

Steel is infinitely recyclable and the overall recycling rate of steel is estimated to be as high as 80 per cent. However, the strength of the demand for steel means that scrap is only able to account for about 40 per cent of inputs for steelmaking.

The race to remake

steelmaking

The dominant steelmaking technology today involves using coking furnaces to heat coal to make coke, which is then put into a blast furnace with iron ore. The coke is converted into carbon monoxide, which extracts the oxygen from the iron ore, leaving elemental iron, which melts to the bottom of the furnace. That liquid iron is then sent on to the basic oxygen furnace to have its carbon level set, turning it into steel.

Most of the emissions come from getting the oxygen off the iron ore, and that is where the green alternatives come in. Instead of blast furnaces, a technology called direct reduction of iron (DRI) pelletises the iron ore before running synthetic gas (hydrogen and carbon monoxide) through it. The synthetic gas takes away the oxygen as steam, leaving solid elemental iron, which a producer can then sell or melt in an electric arc furnace. To decarbonise DRI, producers can either add carbon capture and storage technology to catch the emitted CO2. Or, if they have an external heating source, they can use pure hydrogen instead of coal, in a process called H2-DRI.

Alternatively, there are two types of electrolysis technologies: aqueous electrolysis submerges the iron ore in acid and zaps it with electricity, making the oxygen bubble off; and molten oxide electrolysis heats powdered iron ore with electrodes until it melts and releases the oxygen.

“At present the most advanced methods of green steel production involve the direct reduction of iron ore using hydrogen,” Walsh said.

Indeed, green hydrogen is seen as central to the decarbonisation of steelmaking. Substituting coal with natural gas can reduce the carbon intensity of steel by 50 per cent; but if the hydrogen is generated from electrolysis – and the whole process electrified using renewable energy – then the carbon intensity can be reduced by 95 per cent. However, in contrast to coal, hydrogen is difficult to transport.

“The costs of producing and transporting hydrogen may change the equation in terms of which regions are more or less likely to be able to sustain a competitive green steel industry,” he said.

Globally, the green steel industry is still in its infancy. In terms of low-carbon steel, at the moment there is only Aço Verde do Brasil’s 0.6 Mtpa biomass-fuelled green steel plant in operation in Brazil. The major focus outside of this has been on the deployment of a handful of natural gas-fuelled ironmaking and steelmaking plants geared towards a longer-term transition to green hydrogen. The majority of steelmakers – at least those with declared targets – are aiming to be carbon neutral by 2050; however, there’s momentum growing in Europe with Sweden’s SSAB and Germany’s Salzgitter both setting targets in the early-2030s.

“Collectively, there’s a lot of activity going on in the EU, especially in Sweden, Germany and Spain,” Haynes said. “This is likely due to a higher market appetite for green steel and a supportive regulatory environment.”

When the EU’s Carbon Border Adjustment Mechanism arrives in 2026, it will impose a tariff on carbon-intensive imports such as steel. The mechanism is designed to prevent carbon leakage, protecting the emergent green steel industry from direct competition with non-green producers.

According to Haynes, H2 Green Steel is the most advanced of the European cohort. Construction has started on a five Mtpa green steel plant in Boden, Sweden, to be operational by 2030 using the Hybrit method of direct reduction via hydrogen. Outside of the EU, Vulcan Green Steel has also started construction on a five Mtpa facility in Duqm, Oman.

Sparking Australia's

green steel potential

Australia has all the natural advantages and trade relationships to make it a key green steel hub of the future. As well as being the world’s largest exporter of iron ore, supplying key markets in Asia, the country has a strong engineering workforce, ports and industrial nous. The production of green steel requires all these elements, as well as world-class renewable energy potential to power green ironmaking and steelmaking.

Australia hasn’t built a new steel mill in more than three decades. But that is about to change with the Collie green steel recycling mill set to be operational by 2026 and a planned hydrogen direct reduced iron (DRI) plant also on the cards for 2028.

The recently announced Future Made in Australia framework also suggests the nation has the political will to pursue green steel, particularly hydrogen-based to deploy a 1.5 Mtpa electric arc furnace in the coming years, initially using hydrogen from natural gas, but with an aim to transition to green hydrogen in the longer term; and Green Steel WA’s project to develop a 0.5 Mtpa electric arc furnace in Western Australia.

Looking ahead, the two main challenges it faces are shared by its competitors: developing green steel technologies that can process lower-quality iron ore; and reducing the cost of hydrogen production enough to make green steel price-competitive.

For the latter, Haynes believes the country should look to invest in developing industrial storage of hydrogen in underground salt structures, which can be up to 90 per cent cheaper than above-ground storage.

For Dr Changlong Wang, a research fellow at Monash University, the key will be advancing the country’s hydrogen production capabilities, specifically through large-scale electrolysers.

Investing in H2-DRI processes and developing electric arc furnaces to be powered by renewable energy are other vital steps for the industry, Wang said. And the strategic co-location of hydrogen production facilities with iron ore mining operations could further optimise costs and logistics, making Australian green steel more competitive globally.

While Australia produces vast amounts of the raw materials needed for steel, it produces very little of that steel onshore. In fact, more than 20 per cent of the steel used in the country is currently imported from overseas.

“We face an uphill battle if our goal is to compete directly with international steel manufacturers in other countries, who benefit from pre-existing supply chains, production facilities and industry expertise,” Walsh said.

Image captions

But trade in DRI could be a “win-win” that allows Australia to leverage its natural advantages in raw materials and renewable energy, while helping its trading partners to decarbonise their existing heavy industry. A related engineering challenge, however, would be the adaptation of ports and other infrastructure to help Australia move up that steel value chain to export H2-DRI instead of iron ore.

“In short, while technical innovation is needed, engineers will need to operate in a fast-moving policy and business environment, building our capabilities, learning from what others are doing, and helping authorities to plan ahead,” Leach said.

The federal government has demonstrated commitment to developing the green steel industry through several key initiatives. The $2 billion Hydrogen Headstart program, and its follow-up with another $2 billion, are significant steps, alongside the Future Made in Australia Fund fostering innovation and manufacturing capabilities. The $2 per kilogram tax credit for green hydrogen production incentivises the transition by lowering production costs. The South Australian government has also supported the industry by fast-tracking land approvals and infrastructure development.

But more is needed, Wang said. Skills development will be key, including workforce training programs focused on renewable energy technologies, hydrogen production and advanced steelmaking processes. The government should also provide further financial incentives such as subsidies, tax breaks and low-interest loans to encourage investment in green steel technologies; and carbon pricing mechanisms can make green steel more competitive by internalising the environmental costs of traditional steel production.

“And international partnerships and export strategies will help Australia access global markets for green steel,” Wang said.

Nonetheless, the good news for Australia is that it has all the raw materials the world requires to get to net zero; allowing the country to decarbonise at home while helping others follow suit abroad. Overall, the Superpower Institute predicts that Australia could reduce international emissions by seven per cent.

“This is Australia’s superpower potential,” Leach said.

More from create

Read more about decarbonising the building blocks of our infrastructure:

What Australia must do to not miss out on the green steel boom

Australia’s main iron ore exports may not work with green steelmaking. Here’s what we must do to prepare.

What are the challenges and opportunities of low-carbon concrete?

Engineers who have gone big with low-carbon concrete walk through the challenges, considerations and lessons learned from embracing new forms of concrete.

Why electrification is critical to decarbonising the mining sector

Decarbonisation starts with improving material and energy efficiency at all stages of the mineral’s extraction and lifecycle.